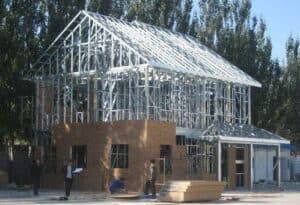

You can build a two-story house in Guyana using light steel framing with proper engineering design, typically using 150-200mm deep C-studs with 1.2-2.0mm thickness, engineered connections, and appropriate foundation systems, meeting local building codes through structural calculations that account for tropical wind loads, seismic requirements, and long-span floor systems with deflection limits.

Light steel framing supports two-story residential construction through engineered structural design using appropriate stud depths and thicknesses. 150-200mm deep C-studs with 1.2-2.0mm gauge provide adequate load capacity for residential applications. Engineered connections between floors and roof systems ensure structural continuity and load transfer. Foundation design must accommodate steel frame loads with proper anchor bolts and base connections. Local building codes require structural engineering approval for multi-story steel frame residential construction.

From my extensive experience with light steel systems, I've observed that proper engineering design eliminates most structural concerns about multi-story residential construction using steel framing.

How to Attach Heavy Kitchen Cabinets to Light Steel Stud Walls?

Attach heavy kitchen cabinets to light steel stud walls using structural backing plates, heavy-duty toggle anchors rated for 75-100kg per point, or continuous steel angle brackets fastened through multiple studs, with cabinet loads distributed across minimum 3 studs and maximum 40kg per linear meter for upper cabinets and 60kg per linear meter for base cabinets including contents.

Structural backing plates installed during construction provide solid attachment points for heavy cabinet installations. Heavy-duty toggle anchors rated 75-100kg capacity penetrate steel studs creating secure mounting points. Continuous steel angles distribute cabinet loads across multiple studs preventing localized stress concentrations. Load distribution requires cabinet attachment to minimum three studs for upper cabinets and four studs for heavy base units. Weight limits of 40kg per linear meter for wall cabinets and 60kg per linear meter for base cabinets ensure structural safety.

Cabinet Attachment Methods

Different approaches for securing cabinets to light steel stud walls by weight category.

| Cabinet Type | Weight Range | Attachment Method | Fastener Rating | Stud Requirements |

|---|---|---|---|---|

| Light Upper Cabinets | 15-25kg | Standard toggles | 50kg per point | 2 studs minimum |

| Heavy Upper Cabinets | 25-40kg | HD toggle anchors | 75kg per point | 3 studs minimum |

| Base Cabinets Empty | 30-50kg | Steel angles | 100kg per point | 3 studs minimum |

| Base Cabinets Loaded | 50-80kg | Backing plates | 150kg per point | 4 studs minimum |

| Appliance Cabinets | 80-120kg | Structural backing | 200kg per point | Full width support |

Structural backing plates provide most reliable attachment for heavy installations.

Fastener Selection Guide

Appropriate fasteners for different cabinet weights and steel stud applications.

| Fastener Type | Load Capacity | Steel Thickness | Installation | Cost Factor |

|---|---|---|---|---|

| Standard Toggle | 25-50kg | 0.5-0.8mm | Simple | Low |

| Heavy-Duty Toggle | 50-75kg | 0.8-1.2mm | Moderate | Medium |

| Steel Grip Anchors | 75-100kg | 1.0-1.5mm | Complex | Medium |

| Through-Bolt System | 100-150kg | Any thickness | Professional | High |

| Structural Backing | 150kg+ | Not applicable | Pre-installation | Highest |

Through-bolt systems provide maximum holding power for heavy applications.

Load Distribution Strategies

Methods to properly distribute cabinet loads across light steel stud walls.

| Distribution Method | Load Capacity | Installation Complexity | Reliability | Application |

|---|---|---|---|---|

| Single Point Attachment | 25kg max | Simple | Poor | Light items only |

| Two-Point Distribution | 50kg max | Moderate | Fair | Standard upper cabinets |

| Three-Point Distribution | 75kg max | Moderate | Good | Heavy upper cabinets |

| Continuous Steel Angle | 100kg+ | Complex | Excellent | Base cabinet runs |

| Full Backing System | Unlimited | Pre-construction | Excellent | Complete kitchen |

Continuous steel angles provide best balance of capacity and installation complexity.

Are Steel Frame Houses More Fire-Resistant Than Traditional Block Houses?

Steel frame houses with proper fire-rated assemblies provide superior fire resistance compared to traditional block houses, with steel maintaining structural integrity longer than concrete block which can spall and crack under extreme heat, while steel frame systems achieve 1-4 hour fire ratings through gypsum board protection and non-combustible insulation materials.

Steel framing maintains structural integrity at high temperatures without spalling or explosive failure common in concrete block construction. Fire-rated assemblies using multiple layers of fire-rated gypsum board provide 1-4 hour protection depending on wall configuration. Non-combustible insulation such as mineral wool enhances fire performance while providing thermal protection. Predictable behavior of steel under fire conditions allows better emergency response compared to unpredictable block failure. Lighter structural loads reduce collapse risks during fire events.

Fire Resistance Ratings

Comparative fire performance of different wall assemblies and construction types.

| Wall Assembly | Fire Rating | Steel Temperature | Block Performance | Structural Integrity |

|---|---|---|---|---|

| Single Layer Gypsum | 30 minutes | 540°C | Cracking starts | Steel: Good, Block: Fair |

| Double Layer Gypsum | 1 hour | 425°C | Spalling begins | Steel: Excellent, Block: Poor |

| Triple Layer System | 2 hours | 315°C | Severe damage | Steel: Excellent, Block: Failed |

| Special Fire Systems | 3-4 hours | 260°C | Complete failure | Steel: Good, Block: Collapsed |

Steel frame systems maintain structural capacity longer than block construction.

Fire Protection Strategies

Methods to enhance fire resistance in steel frame residential construction.

| Protection Method | Fire Rating Improvement | Cost Impact | Installation Complexity | Effectiveness |

|---|---|---|---|---|

| Standard Gypsum Board | 30-60 minutes | Baseline | Simple | Good |

| Fire-Rated Gypsum | 1-2 hours | +15% | Simple | Excellent |

| Mineral Wool Insulation | +30 minutes | +25% | Moderate | Very Good |

| Intumescent Coatings | +60 minutes | +40% | Complex | Excellent |

| Concrete Encasement | 3+ hours | +100% | Very Complex | Excellent |

Fire-rated gypsum board provides best cost-effective fire protection.

Performance Under Fire Conditions

Behavioral comparison of steel frame versus block construction during fire events.

| Fire Condition | Steel Frame Response | Block Construction Response | Safety Implication |

|---|---|---|---|

| Initial Heating | Thermal expansion | Differential expansion | Steel: Predictable, Block: Variable |

| Sustained Heat | Strength reduction | Spalling and cracking | Steel: Gradual, Block: Sudden |

| Extreme Temperature | Controlled deflection | Catastrophic failure | Steel: Safer, Block: Dangerous |

| Cooling Phase | Recovers strength | Permanent damage | Steel: Repairable, Block: Replace |

Steel frame construction provides more predictable and safer fire performance.

What Are the Load-Bearing Limits of Light Gauge Steel Studs for Residential Homes?

Light gauge steel studs for residential homes support 800-2400kg vertical loads depending on stud depth (92-200mm), thickness (0.8-2.0mm), and height (2.4-4.5m), with 146mm x 1.2mm studs at 600mm spacing supporting typical two-story residential loads, while 200mm x 1.5mm studs handle heavy roof loads and multi-story applications requiring engineered calculations.

92mm deep studs with 1.0mm thickness support 800-1200kg vertical loads for single-story applications with standard residential loading. 146mm deep studs with 1.2mm thickness handle 1200-1800kg loads suitable for two-story construction with proper spacing. 200mm deep studs with 1.5-2.0mm thickness support 1800-2400kg loads for heavy roof systems and multi-story buildings. Load capacity decreases with increased stud height requiring closer spacing or heavier gauge steel. Engineering calculations determine exact load limits based on specific building conditions and loading combinations.

Load Capacity by Stud Configuration

Maximum allowable loads for common residential steel stud configurations.

| Stud Size | Thickness | Height | Vertical Load | Lateral Load | Residential Application |

|---|---|---|---|---|---|

| 92mm x 0.8mm | 0.8mm | 2.4m | 600kg | 150kg | Light partitions |

| 92mm x 1.0mm | 1.0mm | 3.0m | 800kg | 200kg | Single story walls |

| 146mm x 1.2mm | 1.2mm | 3.6m | 1200kg | 300kg | Two-story load bearing |

| 146mm x 1.5mm | 1.5mm | 4.0m | 1500kg | 400kg | Heavy residential |

| 200mm x 1.5mm | 1.5mm | 4.5m | 1800kg | 500kg | Multi-story construction |

| 200mm x 2.0mm | 2.0mm | 4.5m | 2200kg | 650kg | Maximum residential |

146mm x 1.2mm studs are most common for residential load-bearing applications.

Load Factors and Safety Margins

Engineering factors affecting actual usable load capacity in residential construction.

| Load Factor | Standard Multiplier | Design Impact | Safety Margin | Code Requirement |

|---|---|---|---|---|

| Dead Load | 1.2 factor | Building weight | 2.5:1 minimum | IBC Section 1605 |

| Live Load | 1.6 factor | Occupancy loads | 3:1 minimum | IBC Section 1607 |

| Snow Load | 1.6 factor | Roof loading | 2.5:1 minimum | ASCE 7 Chapter 7 |

| Wind Load | 1.6 factor | Lateral forces | 2:1 minimum | ASCE 7 Chapter 27 |

| Seismic Load | Variable | Dynamic forces | Variable | IBC Section 1613 |

Load factors significantly reduce usable capacity from theoretical maximums.

Residential Loading Scenarios

Typical load requirements for common residential applications and appropriate stud selection.

| Application | Dead Load | Live Load | Total Load | Recommended Stud | Spacing |

|---|---|---|---|---|---|

| Interior Partition | 50kg/m | 0kg/m | 50kg/m | 92mm x 0.8mm | 600mm |

| Exterior Wall | 150kg/m | 100kg/m | 250kg/m | 146mm x 1.0mm | 600mm |

| Load-Bearing Wall | 200kg/m | 200kg/m | 400kg/m | 146mm x 1.2mm | 400mm |

| Beam Support | 300kg/m | 400kg/m | 700kg/m | 200mm x 1.5mm | 300mm |

| Heavy Roof Load | 400kg/m | 200kg/m | 600kg/m | 200mm x 1.5mm | 400mm |

Load-bearing walls require minimum 1.2mm thickness with appropriate depth.

Deflection and Serviceability Limits

Performance criteria beyond ultimate strength that affect residential steel stud selection.

| Performance Criteria | Limit | Impact | Design Consideration | User Experience |

|---|---|---|---|---|

| Vertical Deflection | L/360 | Floor/ceiling sag | Stud spacing | Cracking issues |

| Lateral Deflection | H/120 | Wall movement | Bracing requirements | Door/window problems |

| Vibration Control | Perceptible | Floor bounce | Stiffness design | Comfort concerns |

| Long-term Creep | 2x initial | Progressive sag | Material selection | Maintenance needs |

Deflection limits often control design more than ultimate strength.

Conclusion

Two-story houses can be built using light steel framing with proper engineering design using 150-200mm deep C-studs with 1.2-2.0mm thickness, engineered connections, and appropriate foundations meeting local building codes. Heavy kitchen cabinets attach to light steel walls using structural backing plates, heavy-duty toggle anchors rated 75-100kg per point, or continuous steel angles with loads distributed across minimum 3 studs. Steel frame houses are more fire-resistant than traditional block houses through fire-rated assemblies providing 1-4 hour ratings with steel maintaining structural integrity longer than spalling concrete blocks. Light gauge steel studs support 800-2400kg vertical loads depending on depth, thickness, and height with 146mm x 1.2mm studs handling typical two-story residential loads at 600mm spacing. Success with light steel residential construction requires understanding that proper engineering design enables multi-story construction with appropriate member sizing, cabinet attachment methods must distribute loads across multiple studs using appropriate fasteners, fire resistance depends on complete assembly design rather than base materials alone, and load-bearing capacity varies significantly with stud configuration requiring professional calculations for specific applications, making system-based design essential for realizing the full potential of light steel framing in residential construction.