Finding reliable building materials challenges construction professionals worldwide. Poor quality products cause project delays and cost overruns. Many suppliers promise excellence but fail to deliver consistent results.

As China's leading gypsum board manufacturer with over 20 years of experience, we combine high-quality production, integrity, innovation, and service excellence to earn long-term trust from customers across Asia, Africa, America, and Europe through internationally certified building solutions.

I started my career working on construction sites. I witnessed firsthand how substandard materials created nightmare scenarios for contractors. Warped boards forced workers to restart entire wall sections. Moisture damage ruined finished projects. These experiences shaped my commitment to manufacturing excellence. Today, our facility produces materials that prevent these costly problems from occurring.

Precision Manufacturing: Does Excellence Really Start from Material to Finished Board?

Poor raw materials create cascading quality problems throughout production. Inconsistent mixing ratios produce weak boards. Inadequate drying causes dimensional instability. These manufacturing defects cost customers money and reputation damage.

Our 140,000 square meter production facility uses advanced imported production lines and automated equipment with strict process controls from raw material selection to board formation, ensuring stable and balanced product quality across our gypsum board, PVC ceiling, and perforated acoustic board series.

Our manufacturing process follows rigorous quality protocols at every stage. Raw material selection begins with supplier audits and batch testing. We source high-grade gypsum that meets strict purity standards. Automated mixing systems ensure consistent ratios across every production run. Computer-controlled forming machines create uniform thickness and smooth surfaces.

The three-stage quality inspection system represents our commitment to excellence. Our experienced quality control team includes 20 dedicated technicians who monitor production continuously. Stage one testing occurs during material preparation. Stage two checks occur during board formation. Stage three verification happens before packaging and shipment.

| Production Stage | Quality Control Measures | Acceptance Criteria |

|---|---|---|

| Raw Materials | Chemical composition analysis | 95% minimum purity |

| Board Formation | Thickness and density monitoring | ±0.5mm tolerance |

| Final Inspection | Visual and dimensional checks | Zero defect tolerance |

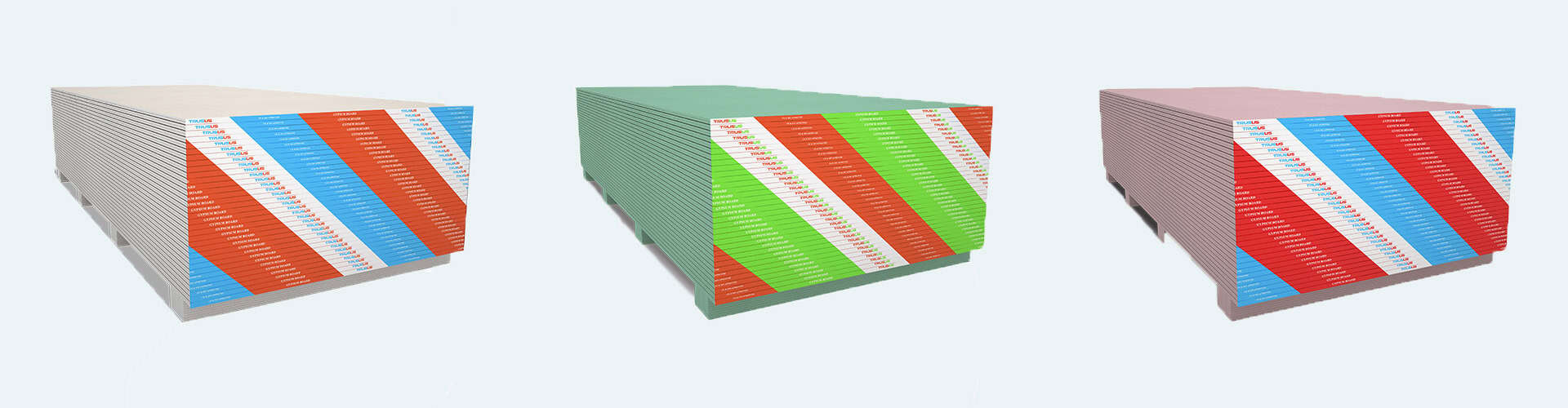

Modern building projects demand materials that meet multiple performance requirements. Fire resistance protects occupants during emergencies. Moisture resistance prevents mold growth in humid environments. Environmental safety ensures healthy indoor air quality. Ease of installation reduces construction time and labor costs. Our product series addresses each of these critical needs.

Continuous improvement drives our manufacturing philosophy. We invested heavily in automated systems that eliminate human error. Temperature monitoring ensures optimal curing conditions. Quality data tracking identifies trends before problems develop. Regular equipment maintenance prevents production disruptions. These systematic approaches maintain consistent output quality that customers depend on.

Quality Assurance: Can Certification Really Build Global Trust?

International projects require verified compliance with regional standards. Customers face regulatory challenges when importing uncertified materials. Certificate gaps cause customs delays and project shutdowns. These compliance failures damage business relationships and create legal liability.

We maintain comprehensive international certifications including ISO9001, CE, NZ/AS, CO, SONCAP, FTA, COC, and PVOC, ensuring our products meet global building standards and enabling smooth market entry and project implementation worldwide.

Each certification represents significant investment in system improvements and staff training. ISO9001 certification required documented quality management procedures across all departments. We standardized work instructions, established measurement protocols, and implemented corrective action systems. This foundation supports all other certification achievements.

CE marking opens European market access through technical compliance verification. Independent testing laboratories evaluate product performance against European standards. Documentation requirements include technical specifications, test reports, and declaration of conformity. This certification process validated our manufacturing capabilities against world-class benchmarks.

Regional certifications address specific market requirements. SONCAP certification enables entry into Nigeria's growing construction sector. NZ/AS compliance supports projects in Australia and New Zealand. COC verification facilitates Middle Eastern market access. Each certification expands our global reach while demonstrating commitment to local standards.

The certification maintenance process keeps our systems sharp. Annual surveillance audits examine production records, test results, and employee competency. Auditors conduct unannounced facility inspections. They interview workers about procedures. They verify calibration records for measuring equipment. This ongoing scrutiny maintains certification validity and operational excellence.

Customers benefit from our comprehensive certification portfolio through reduced project risk. Certified products eliminate compliance uncertainties. Pre-approved materials accelerate project approvals. Documented quality systems provide liability protection. These advantages create competitive differentiation that customers value highly.

Customer-Centric Service: How Does This Drive International Success?

Poor communication destroys international business relationships. Time zone differences create response delays. Language barriers cause misunderstandings. Cultural differences lead to expectation gaps. These service failures cost customers money and damage long-term partnerships.

We deliver exceptional customer service through 10-minute email response times, comprehensive support from pre-sales consultation and sample provision to post-delivery technical support and logistics tracking, backed by extensive international market experience and localized solutions.

Fast response times solve problems before they escalate into crises. Our customer service team operates across multiple time zones to ensure immediate attention. When customers send urgent inquiries, they receive acknowledgment within minutes. Technical questions get routed to specialists who provide detailed answers. Emergency situations trigger escalation protocols that mobilize resources quickly.

Our service approach covers the complete project lifecycle from initial inquiry to final delivery. Pre-sales consultation includes technical specification review and application guidance. Sample provision allows customers to verify quality before placing orders. Production updates keep customers informed about manufacturing progress. Shipping coordination ensures timely delivery to project sites.

International market expertise differentiates our service quality from domestic-focused competitors. We understand regional building codes and certification requirements. Our team knows customs procedures and documentation needs. We maintain relationships with reliable freight forwarders in major markets. This knowledge prevents delays and reduces customer stress during critical project phases.

| Service Area | Response Time | Support Level |

|---|---|---|

| Email Inquiries | 10 minutes | Technical specialists |

| Sample Requests | 24 hours | Express shipping |

| Order Updates | Daily | Production tracking |

| Emergency Issues | Immediate | Management escalation |

Cultural sensitivity enhances customer relationships across diverse markets. Asian customers appreciate detailed technical documentation. African clients value personal relationship building. American buyers focus on efficiency and reliability. European customers prioritize environmental compliance. Understanding these preferences helps us serve each market effectively.

Technology integration streamlines customer interactions and reduces communication friction. Online order tracking provides real-time shipment visibility. Digital documentation eliminates paperwork delays. Video conferencing enables face-to-face meetings despite geographic distances. Mobile apps allow customers to access information anytime and anywhere.

Conclusion

Through manufacturing excellence, international certifications, and customer-focused service, we build lasting partnerships that support global construction industry growth and innovation.