When I talk to clients about drywall, one question always appears early in the conversation — “What is drywall actually made of?” Most people still treat it as a simple surface material, but drywall is much more than that: it’s part of a system that defines how comfortable and efficient our interiors feel.

The material used for drywall is gypsum, a naturally occurring mineral composed of calcium sulfate dihydrate (CaSO₄·2H₂O). It is transformed through heating, rehydration, and paper lamination into stable, fire-resistant panels for wall and ceiling systems.

This single mineral, properly engineered, creates an interface that controls moisture, sound, and air quality. Drywall doesn’t just decorate; it shapes the indoor environment.

What Metal Is Used for Drywall?

People often confuse drywall panels with the framework that supports them. They ask, “Is there metal inside the drywall itself?” The answer requires understanding the system, not just the sheet.

The metal used in drywall systems is galvanized steel, formed into light gauge framing known as metal studs. These studs create the skeleton for walls and ceilings, providing strength, fire resistance, and long-term shape stability without adding excessive weight.

Why Galvanized Steel Matters

| Component | Function | Benefit |

|---|---|---|

| Metal Studs | Structural support | Prevent warping and shrinkage |

| Metal Track | Base and top connectors | Keep stud alignment |

| Galvanization Layer | Zinc protection against rust | Extends lifespan |

| Screw Fasteners | Secure board to frame | Ensure rigidity and precision |

Steel framing isn’t part of the drywall board but part of the drywall system. It allows construction to achieve precision and lightweight durability at the same time.

What Material Is Used for Drywall?

This question may sound simple, but it opens the door to how materials define comfort and fire safety.

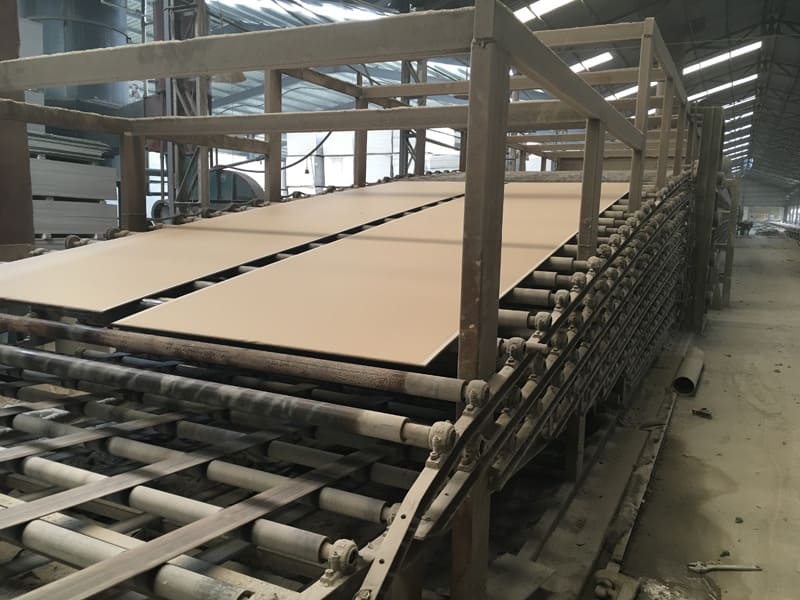

Drywall panels are made from gypsum plaster sandwiched between heavy paper liners. The gypsum core may include additives like fiberglass or mica for improved fire resistance or moisture control.

Breakdown of Drywall Composition

| Layer | Material | Purpose |

|---|---|---|

| Front Paper | Recycled cellulose fiber | Smooth finish for painting |

| Gypsum Core | Calcium sulfate dihydrate | Structure and fire resistance |

| Back Paper | Reinforced paper liner | Structural backing |

| Optional Additives | Fiberglass, foaming agents | Enhanced fire/moisture resistance |

Each layer contributes to the balance between structural integrity and environmental performance. Together, they make drywall both safe and breathable.

Is Drywall 100% Gypsum?

Nearly every client I meet asks this question, and I always enjoy answering it because it helps clarify how engineered materials really work.

No, drywall is not 100% gypsum. While gypsum forms the primary ingredient—around 70–90% of the total volume—other additives, paper liners, and binders help define its mechanical and surface properties. These layers function together to prevent cracking, control weight, and allow smooth finishes.

Why It’s Not Pure Gypsum and Why That Matters

| Composition Element | Role | Impact |

|---|---|---|

| Gypsum (CaSO₄·2H₂O) | Base structure | Provides strength and fire resistance |

| Paper Liners | Encapsulation | Adds durability and easy finishing |

| Foaming/Binder Agents | Density control | Makes board lightweight yet stable |

| Glass Fiber | Thermal reinforcement | Improves fire performance |

Purity isn’t the goal—system stability is. The combination ensures drywall resists deformation and maintains surface uniformity throughout building life cycles.

Which Mineral Is Used for Drywall?

At its heart, drywall is based on one mineral that has quietly supported the construction world for over a century: gypsum.

Gypsum, or calcium sulfate dihydrate, forms naturally in sedimentary environments and can also be produced synthetically from flue-gas desulfurization processes. When processed correctly, it becomes a sustainable, recyclable building mineral used in nearly every interior wall.

Understanding Gypsum’s Role in Building Sustainability

| Aspect | Description | Benefit |

|---|---|---|

| Natural Gypsum | Mined mineral | High stability and whiteness |

| Synthetic Gypsum | Byproduct recovery | Environmental reuse |

| Recyclability | Can be reprocessed | Reduces waste |

| Hygroscopic Nature | Regulates humidity | Enhances indoor comfort |

Gypsum is not just a mineral—it’s an environment-balancing material. It absorbs and releases moisture based on humidity, making interiors healthier and more stable.

Dive Deeper: Drywall as an Environmental System

In practice, drywall systems go far beyond mere wall panels. When combined with galvanized framing, acoustic insulation, and joint finishing, they form a complete space management system.

Drywall influences thermal comfort, sound absorption, and indoor air quality. It’s the foundation of modern energy-efficient design—an interface between humans and buildings.

| Function | System Interaction | Outcome |

|---|---|---|

| Moisture Regulation | Gypsum’s hygroscopic nature | Balanced humidity indoors |

| Acoustic Control | Integrated insulation layer | Reduced noise transmission |

| Fire Protection | Noncombustible gypsum core | Increased safety |

| Energy Efficiency | Lightweight partition system | Faster heating/cooling response |

| Aesthetic Finish | Paper liner + joint compound | Smooth, paintable surface |

When seen as a system, drywall becomes central to achieving safe, comfortable, sustainable indoor environments—not just to dividing space.

Conclusion

Drywall isn’t simply gypsum or paper—it’s an engineered mineral system working with metal framing to regulate acoustic, thermal, and humidity balance. The key mineral is gypsum, but its value lies in how it collaborates with structure and environment to build spaces that breathe.