Many assume partition wall construction follows simple linear steps, but understanding system integration ensures successful installation. Partition wall building involves coordinating structural elements, material properties, and performance requirements rather than just following assembly procedures.

Building a partition wall requires planning layout and measuring space, installing ceiling and floor tracks, placing vertical studs at proper spacing, installing drywall sheets with correct fastening patterns, and finishing joints with tape and compound for professional results.

Through years of drywall manufacturing and installation troubleshooting, I learned that successful partition construction depends on understanding system interactions and performance requirements rather than just following mechanical steps, with proper planning and execution ensuring long-term wall performance and durability.

How Many Screws Should You Put in a 6-12mm Sheet of Drywall?

Understanding proper screw spacing ensures structural integrity and prevents installation problems. Screw density affects holding power, wall performance, and material costs while preventing common issues including sagging, cracking, and fastener failure over time.

A 6-12mm drywall sheet requires screws spaced 6-8 inches apart on ceiling applications and 8-12 inches on walls, with approximately 35-50 screws per 4x8 foot sheet depending on stud spacing and application requirements for optimal holding power and performance.

Comprehensive Drywall Fastener Analysis and Installation Requirements

Drywall fastener spacing involves structural requirements, material properties, and performance optimization that determine proper screw density for different applications. During my experience working with drywall installation failures and fastener problems, I learned that proper fastener spacing balances holding power with cost efficiency while preventing common installation problems.

Screw spacing requirements vary by application with ceiling installations requiring closer spacing due to gravity loads while wall applications allow wider spacing. Proper spacing prevents sagging while optimizing material usage and installation efficiency.

Ceiling applications demand 6-8 inch screw spacing due to gravity loading that creates continuous downward force on drywall sheets. Closer spacing distributes loads more effectively while preventing sagging and joint failure over time.

Wall applications typically allow 8-12 inch screw spacing since gravity loads are supported by floor tracks while lateral forces are minimal. Appropriate wall spacing provides adequate holding power while reducing fastener requirements and installation time.

Stud spacing affects fastener requirements with 16-inch stud centers requiring different screw patterns than 24-inch spacing. Closer stud spacing provides more fastening points while wider spacing may require additional fasteners per stud.

Edge fastening requires screws placed 3/8 to 1/2 inch from sheet edges to prevent paper tearing while ensuring adequate holding power. Proper edge distance prevents installation problems while maintaining sheet integrity.

Field screw placement follows systematic patterns that distribute loads evenly across sheet surfaces while providing adequate attachment to framing members. Systematic placement ensures consistent performance while simplifying installation procedures.

Fastener penetration requirements specify minimum engagement into framing members to ensure adequate holding power, typically requiring 5/8 to 3/4 inch penetration into wood studs or appropriate engagement for metal framing systems.

Special applications including fire-rated assemblies, high-moisture areas, or heavy wall coverings may require modified fastener spacing to meet performance requirements. Special conditions often demand closer spacing or enhanced fasteners.

Quality control during installation includes checking fastener depth, spacing verification, and holding power assessment to ensure proper installation. Systematic quality control prevents problems while ensuring long-term performance.

Installation efficiency benefits from systematic fastening patterns that optimize productivity while ensuring adequate attachment. Proper planning reduces installation time while maintaining quality standards.

| Application | Screw Spacing | Screws per 4x8 Sheet | Special Considerations |

|---|---|---|---|

| Ceiling installation | 6-8 inches | 45-60 screws | Gravity load support |

| Wall installation | 8-12 inches | 35-50 screws | Standard applications |

| Fire-rated assembly | 6 inches maximum | 50-70 screws | Code requirements |

| Moisture areas | 8 inches maximum | 40-55 screws | Enhanced attachment |

| Heavy coverings | 6 inches maximum | 50-70 screws | Additional support needed |

| 16" stud spacing | Per pattern | Variable | More attachment points |

| 24" stud spacing | Closer spacing | More per stud | Compensate for spacing |

| Double layer | Per layer requirements | Doubled | Each layer separately |

How to Build a Dry Wall Partition?

Understanding complete drywall partition construction ensures professional results and long-term performance. Drywall partition building involves systematic construction processes that coordinate framing, installation, and finishing for optimal wall performance and appearance.

Building a drywall partition requires measuring and marking layout, installing top and bottom tracks, placing studs at correct spacing, running utilities if needed, installing drywall sheets with proper fastening, and completing joint finishing for professional appearance and performance.

Detailed Drywall Partition Construction Guide and Best Practices

Drywall partition construction involves systematic planning and execution that coordinates multiple construction phases for optimal results. During my experience working with partition installations and construction quality issues, I learned that successful partition building requires understanding system interactions while following proper construction sequences.

Planning phase involves measuring space dimensions, determining wall locations, identifying utility requirements, and selecting appropriate materials that meet performance specifications. Proper planning prevents problems while optimizing construction efficiency and results.

Layout marking includes floor and ceiling locations using chalk lines, laser levels, or traditional measuring tools that establish accurate wall positions. Precise layout ensures straight walls while preventing dimensional problems during construction.

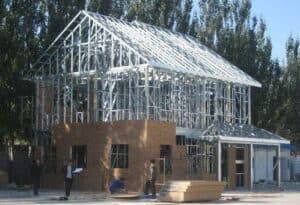

Track installation begins with bottom track attachment to floor surfaces using appropriate fasteners for floor type, followed by top track installation ensuring proper alignment and levelness. Track installation creates the foundation for straight, stable partition construction.

Stud placement follows systematic spacing requirements with studs positioned at specified centers and proper alignment with tracks. Correct stud installation ensures structural integrity while providing adequate attachment points for drywall sheets.

Utility installation occurs after framing completion and includes electrical wiring, plumbing rough-in, or HVAC components that require coordination with partition construction. Utility integration should be completed before drywall installation begins.

Insulation placement improves thermal and acoustic performance through proper material selection and installation techniques that fill stud cavities without compression. Insulation installation should be completed before drywall application.

Drywall installation follows systematic patterns starting with ceiling sheets, then full wall sheets, and finishing with cut pieces. Proper installation sequence minimizes joints while ensuring adequate support and professional appearance.

Fastener installation follows specified spacing patterns with proper screw depth and systematic placement that ensures adequate holding power. Consistent fastener installation prevents problems while optimizing wall performance.

Joint treatment involves tape application, compound finishing, and surface preparation through multiple coating applications that create seamless wall surfaces. Professional joint finishing ensures appearance quality while preventing future problems.

Quality inspection throughout construction identifies problems early while ensuring compliance with specifications and building codes. Systematic quality control ensures professional results while preventing costly corrections.

| Construction Phase | Key Activities | Quality Checkpoints | Common Issues |

|---|---|---|---|

| Planning | Layout, material selection | Measurements, specifications | Inadequate planning |

| Layout marking | Floor/ceiling lines | Accuracy, alignment | Crooked layout lines |

| Track installation | Fastening, alignment | Level, straight | Poor attachment |

| Stud placement | Spacing, alignment | Plumb, spacing | Incorrect spacing |

| Utilities | Wiring, plumbing | Code compliance | Conflicts with framing |

| Insulation | Cavity filling | Coverage, compression | Gaps, compression |

| Drywall installation | Sheet placement, fastening | Alignment, attachment | Gaps, poor fastening |

| Finishing | Joint treatment | Smoothness, coverage | Visible joints |

| Final inspection | Overall quality | Specifications met | Defects, non-compliance |

What Material is Used for Drywall Partitions?

Understanding drywall partition materials helps optimize performance and cost efficiency. Partition materials include structural components, sheet materials, and finishing systems that work together to create complete wall assemblies meeting specific performance requirements.

Drywall partition materials include metal or wood studs for framing, gypsum drywall sheets for surfaces, screws or nails for fastening, joint tape and compound for finishing, plus insulation and vapor barriers when required for enhanced performance.

Comprehensive Material Analysis for Drywall Partition Systems

Drywall partition materials involve multiple component categories that work together to create complete wall systems meeting structural, performance, and aesthetic requirements. During my experience working with material specifications and system optimization, I learned that understanding material interactions ensures proper selection while optimizing cost and performance balance.

Framing materials provide structural support and include metal studs, wood studs, and track systems that create the wall framework. Framing selection affects wall performance, installation efficiency, and long-term durability while influencing other material choices.

Metal stud systems offer dimensional stability, fire resistance, and consistent quality through galvanized steel construction that resists warping and shrinkage. Metal framing provides excellent performance while enabling thinner wall assemblies and improved fire ratings.

Wood stud framing uses dimensional lumber that provides familiar installation methods and good performance for many applications. Wood framing offers cost advantages while providing excellent fastener holding power and ease of modification.

Track systems include top and bottom tracks that secure stud assemblies while providing proper alignment and load distribution. Track selection should coordinate with stud types while providing adequate attachment to floor and ceiling structures.

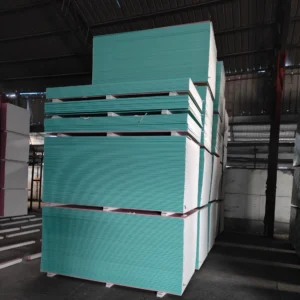

Drywall sheet materials include standard gypsum board, moisture-resistant board, fire-resistant board, and specialty products designed for specific applications. Sheet selection affects wall performance while influencing installation and finishing requirements.

Standard gypsum board provides basic performance for general applications through gypsum core with paper facing that offers good workability and cost efficiency. Standard board works well for most residential and commercial applications.

Moisture-resistant drywall includes enhanced core formulations and facing materials that resist moisture absorption and mold growth in wet areas. Moisture-resistant products extend wall life while preventing moisture-related problems.

Fire-resistant drywall incorporates additives and construction features that improve fire resistance ratings for code compliance and safety requirements. Fire-rated products meet building code requirements while providing enhanced safety performance.

Fastener selection includes screws, nails, and specialty fasteners designed for specific framing and performance requirements. Proper fastener selection ensures adequate holding power while preventing installation problems and long-term failures.

Joint finishing materials include tape, compound, and primer systems that create seamless wall surfaces ready for final finishes. Finishing material quality affects appearance while influencing long-term performance and maintenance requirements.

Insulation products improve thermal and acoustic performance through various material types including fiberglass, mineral wool, and foam products. Insulation selection should coordinate with wall design while meeting performance requirements.

Vapor barriers and air barriers control moisture and air movement through wall assemblies while protecting structural components and maintaining building performance. Barrier materials should coordinate with building design and climate requirements.

| Material Category | Primary Options | Performance Characteristics | Selection Factors |

|---|---|---|---|

| Framing | Metal vs. wood studs | Structural, fire, dimensional | Performance requirements, cost |

| Metal studs | 25ga to 20ga, various depths | Straight, fire-resistant | Commercial applications |

| Wood studs | 2x4, 2x6 dimensional lumber | Strong, workable | Residential, cost-sensitive |

| Drywall Sheets | Standard, moisture, fire-resistant | Function-specific performance | Application requirements |

| Standard 1/2" | General purpose | Basic performance, economical | Most applications |

| Moisture-resistant | Wet area applications | Mold/moisture resistance | Bathrooms, kitchens |

| Fire-resistant 5/8" | Code compliance | Enhanced fire rating | Commercial, multi-family |

| Fasteners | Screws, nails | Holding power, corrosion resistance | Framing type, performance |

| Finishing | Tape, compound systems | Appearance, durability | Quality level, use type |

| Insulation | Fiberglass, mineral wool | Thermal, acoustic performance | Performance requirements |

Conclusion

Building partition walls requires systematic layout, framing, drywall installation, and finishing processes, 6-12mm drywall needs 35-50 screws per sheet with 6-12 inch spacing depending on application, drywall partitions involve complete construction sequences from framing through finishing, and partition materials include metal or wood framing, gypsum sheets, fasteners, and finishing systems.