Ground-floor units in Georgetown suffer from rising damp that ruins finishes. Moisture travels up your walls, causing paint to peel. Use a damp-proof course to block it forever.

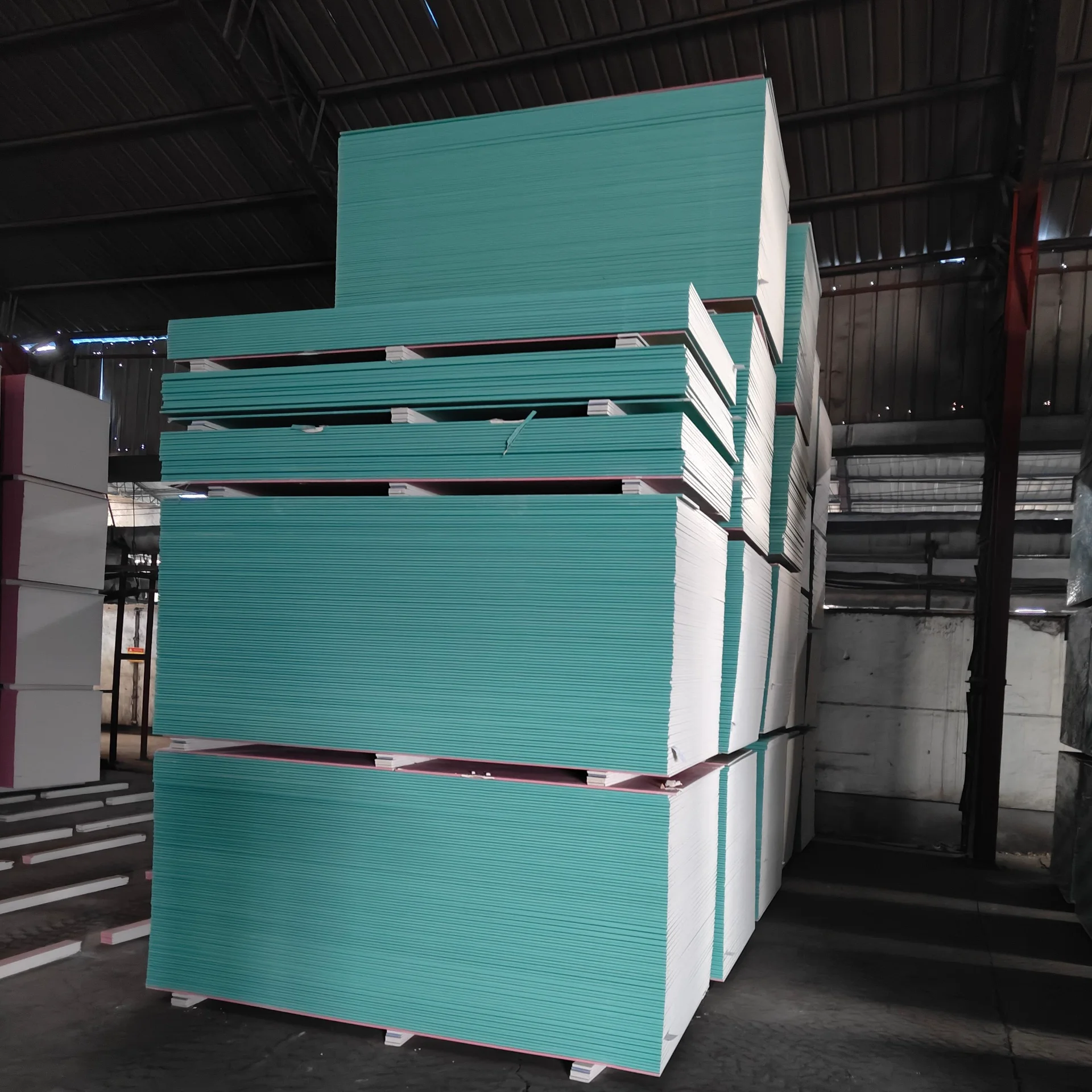

Protect drywall by installing a damp-proof membrane (DPM) between the floor and the light steel track. Use moisture-resistant green gypsum boards for the bottom 4 feet of the wall. This prevents ground moisture from wicking into the material, keeping your walls dry and mold-free.

I have seen many contractors in Georgetown try to fix damp walls by just painting over them. This is a waste of time. The water is coming from the ground, and it is very persistent. Capillary action pulls water up into the gypsum board like a sponge. Once that happens, the core of the board softens and mold begins to grow. For an engineer like Marcin, this is a nightmare because it ruins the air quality and the structural integrity of the wall.

At TRUSUS, we teach people to think about the "thermal break" and the "moisture break." When we install our light steel framing, we put a thick plastic strip or a special foam gasket under the bottom track. This stops the metal from touching the damp concrete floor. Then, we use our moisture-resistant green board. This board has a special core that does not like water. I even tell my clients to leave a 1/2 inch gap between the bottom of the board and the floor. You cover this gap with a baseboard. This small air space ensures that moisture can never jump from the floor to your wall.

| Strategy | Material Needed | Function |

|---|---|---|

| Floor Barrier | DPM Gasket | Stops moisture transfer from slab to track |

| Board Selection | Green Gypsum Board | Resists moisture wicking and mold growth |

| Installation Gap | 1/2 inch Spacing | Prevents direct contact with damp floors |

| Joint Finish | Moisture-proof Compound | Protects seams from humidity |

Why Is PVC Ceiling More Popular Than Wood in Essequibo’s Humid Regions?

Wood ceilings in Essequibo often warp and grow mold due to extreme humidity. This creates a messy look and health risks. Switching to PVC solves these problems instantly.

PVC ceilings are more popular because they are 100% waterproof and do not warp in high humidity. Unlike wood, PVC does not require painting or sanding and is much lighter. It offers a maintenance-free finish that withstands the tropical moisture of Guyana's river regions.

In the humid parts of Essequibo, I have noticed that "Maintenance Fatigue" is a real thing. People get tired of sanding and repainting their wooden ceilings every two years. Wood is a living material. It breathes. When the humidity is 90%, the wood swells. When the sun comes out, it shrinks. This cycle causes cracks and makes the paint flake off. I used to work with wood a lot, but for tropical ceilings, I changed my mind.

PVC is an inorganic material. It does not care about humidity. It stays the same size and shape no matter how much it rains. For someone like Marcin, who wants to reduce project costs over time, PVC is a smart choice. It is also very light. This means the ceiling grid does not have to carry a lot of weight. At TRUSUS, we make PVC panels with beautiful patterns that look like wood or high-end plaster. You get the beauty without the hard work. It is a "fit and forget" solution that lets you spend your time on better things.

| Feature | PVC Ceiling | Timber Ceiling |

|---|---|---|

| Water Resistance | 100% Waterproof | Poor (Absorbs water) |

| Termite Risk | Zero | High |

| Painting Needed | Never | Every 2-3 years |

| Weight | Very Light | Heavy |

Is Gypsum Board Better Than Timber for Termite Prevention in Guyana Homes?

Termites eat through timber frames in Guyana, causing expensive structural damage overnight. You might not even see them until it is too late. Gypsum board and steel are the solution.

Gypsum board and light steel framing are superior to timber because they are inorganic and offer zero food for termites. Using these materials eliminates the need for toxic chemical treatments. This provides long-term peace of mind and saves you thousands in future pest control costs.

I have helped many clients grow their businesses by switching them from wood to steel and gypsum. In Guyana, termites are a massive problem. They love the warm, damp wood found in traditional homes. When I was an employee at a building material factory, I saw people buying wood and then buying expensive poisons to spray on the wood. It made no sense to me. Why build with something that wants to be eaten?

Gypsum is a mineral. Steel is a metal. Neither of these is on the menu for a termite. When you build with a TRUSUS light steel frame system, you are building a fortress. You don't have to worry about the structural "hollow" sounds that come from termite damage. Also, it is much safer for your family. You don't have those toxic chemicals in your walls. Marcin often looks for green building techniques, and avoiding chemical pesticides is a big part of that. It is a cleaner, smarter way to build in the tropics.

| Material | Termite Food Source? | Chemical Treatment? | Structural Risk |

|---|---|---|---|

| Timber | Yes (Cellulose) | Required | High |

| Light Steel | No | None | Zero |

| Gypsum Board | No | None | Zero |

| Plywood | Yes | Required | High |

Does Light Steel Framing Rust in Guyana’s High-Salinity Coastal Areas?

High salinity in Guyana’s air can eat through metal studs in months. Many engineers fear rust will collapse their buildings. You must choose the right coating to survive.

Light steel framing does not rust if it has a high zinc coating like G90 or Z275. These coatings act as a shield against salt air. Using aluminum-zinc alloys further increases resistance, making it perfect for coastal construction where standard steel would fail.

I once worked on a project right on the coast where the salt spray was so thick you could taste it. The contractor used cheap, thin-coated steel he bought from a local trader. Within six months, the studs were covered in red rust. This is a common mistake. People think all steel is the same. It is not. As a manufacturer, I always tell my friends to look at the "Z" or "G" rating on the steel.

For high-salinity areas like the Guyana coast, you need a heavy zinc layer. Standard steel often has a Z60 or Z80 coating. That is okay for inland, but for the coast, you need at least Z275. This means there are 275 grams of zinc per square meter. The zinc "sacrifices" itself to protect the steel underneath. If Marcin is specifying materials for a commercial project near the ocean, he must insist on high-zinc or Aluzinc coatings. At TRUSUS, we prioritize these coatings because we want to bring beauty to every corner—even the salty ones. It costs a little more at the start, but it prevents a total building failure later.

| Coating Grade | Zinc Content | Environment | Durability |

|---|---|---|---|

| Z60 / Z80 | Low | Inland / Dry | 5-10 Years |

| Z120 / Z180 | Moderate | Urban / Mild Humidity | 15-20 Years |

| Z275 (G90) | High | Coastal / High Salinity | 30+ Years |

| Aluzinc | Alloy | Extreme Coastal | 50+ Years |

Conclusion

Building in Guyana requires materials that fight humidity, termites, and salt. Use green board, PVC, and high-zinc steel to ensure your home stays strong and beautiful for decades.