Stop gypsum ceiling sagging in Georgetown's high humidity by using moisture-resistant Type MR gypsum board, reducing joist spacing to 300-400mm centers, installing proper vapor barriers, ensuring adequate ventilation with exhaust fans, and applying mold-resistant primers with fungicidal treatments while maintaining consistent indoor humidity below 60% through dehumidification systems.

Moisture-resistant gypsum board provides enhanced dimensional stability in high humidity through water-repellent additives and modified core composition. Closer joist spacing at 300-400mm centers reduces deflection stress preventing sag formation under moisture loading. Proper vapor barriers on warm side prevent moisture penetration into ceiling cavity. Adequate ventilation removes humid air before condensation occurs on ceiling surfaces. Humidity control below 60% RH prevents material degradation and microbial growth.

From my extensive manufacturing experience in tropical climates, I've learned that ceiling sagging results more from inadequate support and moisture management than material defects.

Are PVC Laminated Gypsum Tiles Mold-Proof for Guyana Coastal Homes?

PVC laminated gypsum tiles provide excellent mold resistance for Guyana coastal homes through impermeable surface barriers that prevent moisture penetration, antimicrobial additives in laminate films, and easy cleaning maintenance, though proper installation with sealed edges and adequate ventilation remains essential for long-term mold prevention in salt-air environments.

Impermeable PVC surface prevents moisture absorption into gypsum substrate eliminating primary mold growth conditions. Antimicrobial additives in laminate films provide active protection against fungal spores and bacterial growth. Easy cleaning maintenance allows regular removal of surface contaminants before mold establishment. Sealed edge systems prevent moisture infiltration at tile joints and perimeter connections. Salt-air resistance through PVC barrier protects underlying gypsum from coastal corrosion.

Mold Resistance Testing

Comparative mold growth testing for different ceiling materials in coastal conditions.

| Material Type | Mold Growth Rate | Surface Protection | Cleaning Ease | Longevity Rating |

|---|---|---|---|---|

| Standard Gypsum | High (7-14 days) | None | Difficult | 2-3 years |

| Painted Gypsum | Moderate (14-21 days) | Minimal | Moderate | 3-5 years |

| PVC Laminated | Very Low (45+ days) | Excellent | Easy | 10-15 years |

| Vinyl Faced | Low (21-30 days) | Good | Easy | 8-12 years |

| Aluminum Faced | None | Excellent | Very Easy | 15+ years |

PVC laminated tiles show significant mold resistance compared to unprotected gypsum.

Coastal Environment Factors

Specific challenges in Guyana coastal areas affecting ceiling performance.

| Environmental Factor | Impact Level | Standard Gypsum | PVC Laminated | Mitigation Required |

|---|---|---|---|---|

| Salt Air Corrosion | High | Severe damage | Protected | Sealed installation |

| Humidity 80-95% | Extreme | Rapid degradation | Resistant | Ventilation essential |

| Temperature Cycling | Moderate | Expansion issues | Stable | Proper fastening |

| UV Exposure | Low | Minimal | Fade resistant | Window treatments |

| Wind-driven Rain | High | Water damage | Protected | Weatherproofing |

Salt air and extreme humidity create challenging conditions for standard materials.

Installation Requirements

Critical installation factors for mold-proof performance in coastal homes.

| Installation Aspect | Standard Practice | Coastal Requirement | Performance Impact | Cost Factor |

|---|---|---|---|---|

| Edge Sealing | Tape joints | Sealant required | Major | +15% |

| Fastener Spacing | 200mm centers | 150mm centers | Moderate | +10% |

| Vapor Barrier | Optional | Essential | Major | +25% |

| Ventilation | Natural | Mechanical required | Major | +40% |

| Primer/Sealer | Standard | Mold-resistant | Moderate | +20% |

Edge sealing and mechanical ventilation are critical for mold prevention.

Best Moisture-Resistant Ceiling Materials for Bathrooms in Tropical Climates?

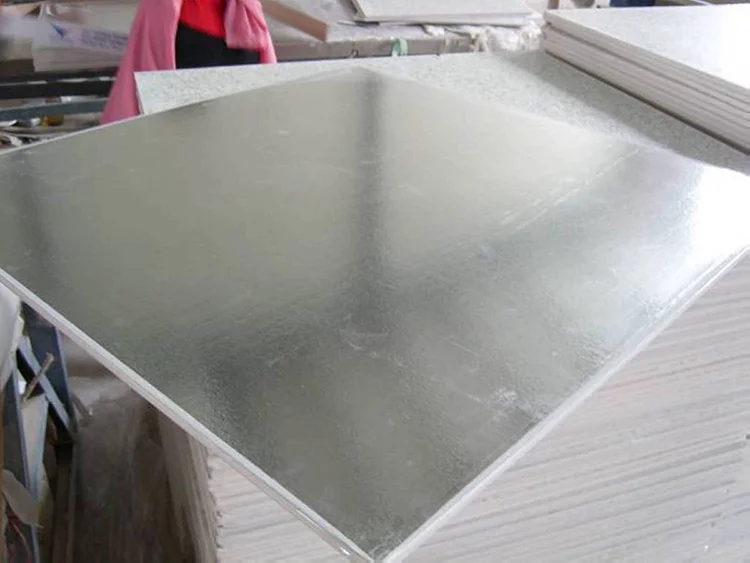

Best moisture-resistant bathroom ceiling materials for tropical climates include aluminum composite panels with antimicrobial coatings, PVC ceiling planks with integrated vapor barriers, fiber cement boards with waterproof membranes, and marine-grade plywood with epoxy sealing, prioritizing materials with zero water absorption and easy maintenance in high-humidity environments.

Aluminum composite panels provide zero water absorption with antimicrobial surface coatings and excellent corrosion resistance. PVC ceiling planks offer integrated vapor barriers, easy installation, and low maintenance with mold-resistant properties. Fiber cement boards deliver dimensional stability with waterproof membrane systems for high-moisture areas. Marine-grade plywood with epoxy sealing provides natural aesthetics with enhanced moisture protection. Easy maintenance cleaning prevents microbial accumulation in humid tropical conditions.

Material Performance Comparison

Detailed analysis of moisture-resistant ceiling materials for tropical bathrooms.

| Material | Water Absorption | Mold Resistance | Installation Ease | Maintenance Level | Cost Factor |

|---|---|---|---|---|---|

| Aluminum Composite | 0% | Excellent | Moderate | Very Low | High |

| PVC Planks | <1% | Excellent | Easy | Low | Moderate |

| Fiber Cement | 5-8% | Good | Difficult | Low | Moderate |

| Marine Plywood | 3-5% | Good | Moderate | Moderate | High |

| Vinyl Tiles | 0% | Excellent | Easy | Very Low | Low |

Aluminum composite provides superior performance but higher initial cost.

Tropical Climate Considerations

Specific factors affecting ceiling material selection in tropical bathrooms.

| Climate Factor | Impact on Materials | Selection Priority | Mitigation Strategy | Long-term Effect |

|---|---|---|---|---|

| Constant Humidity | Material expansion | Dimensional stability | Proper fastening | Critical |

| Temperature Swings | Thermal cycling | Thermal movement | Expansion joints | Moderate |

| Poor Ventilation | Condensation buildup | Vapor resistance | Mechanical exhaust | Critical |

| Salt Air | Corrosion acceleration | Corrosion resistance | Protective coatings | Moderate |

| Mold Spores | Surface contamination | Antimicrobial properties | Easy cleaning | Critical |

Dimensional stability and vapor resistance are most critical factors.

Ventilation Integration

Ceiling material compatibility with ventilation systems in tropical bathrooms.

| Ventilation Type | Material Compatibility | Installation Notes | Performance Benefit | Maintenance Required |

|---|---|---|---|---|

| Exhaust Fans | All materials | Sealed penetrations | Humidity removal | Regular cleaning |

| Natural Ventilation | Limited effectiveness | Passive systems | Minimal benefit | None |

| Whole House Systems | All materials | Integrated design | Excellent control | Professional service |

| Heat Recovery | All materials | Complex installation | Energy efficient | Specialist service |

| Dehumidifiers | All materials | Electrical integration | Direct humidity control | Filter replacement |

Mechanical exhaust is essential regardless of ceiling material choice.

Why is My Plasterboard Ceiling Turning Black, and How to Fix It?

Plasterboard ceilings turn black from mold growth caused by moisture condensation, poor ventilation, thermal bridging creating cold spots, or water leaks creating ideal fungal conditions, requiring immediate moisture source elimination, affected area removal/treatment, improved ventilation installation, and preventive measures like mold-resistant primers and humidity control systems.

Mold growth causes black discoloration when moisture accumulates on ceiling surfaces creating ideal fungal conditions. Poor ventilation allows humid air stagnation leading to condensation and microbial growth. Thermal bridging creates cold spots where water vapor condenses promoting mold establishment. Water leaks from roof or plumbing provide direct moisture for extensive mold growth. Organic materials in standard gypsum provide food source for mold organisms.

Mold Growth Causes

Primary factors leading to black discoloration on plasterboard ceilings.

| Cause | Frequency | Severity | Detection Method | Immediate Action |

|---|---|---|---|---|

| Condensation | Very High | Moderate | Visual moisture | Improve ventilation |

| Roof Leaks | High | Severe | Water stains | Emergency repair |

| Plumbing Leaks | Moderate | Severe | Moisture meter | Professional repair |

| Poor Ventilation | Very High | Moderate | Humidity measurement | Install exhaust fans |

| Thermal Bridging | Moderate | Mild | Thermal imaging | Insulation upgrade |

Condensation and poor ventilation are most common causes in tropical climates.

Remediation Process

Step-by-step process for treating black mold on plasterboard ceilings.

| Remediation Step | Procedure | Materials Required | Safety Precautions | Expected Results |

|---|---|---|---|---|

| Safety Setup | Containment barriers | Plastic sheeting | Respirators/gloves | Work area isolation |

| Moisture Control | Source elimination | Repairs/ventilation | Electrical safety | Dry conditions |

| Mold Removal | Affected area cutting | Disposal bags | Protective equipment | Clean substrate |

| Surface Treatment | Antimicrobial application | Fungicidal solutions | Ventilation required | Sterilized surfaces |

| Replacement | New material installation | Mold-resistant products | Proper ventilation | Restored ceiling |

Moisture control is essential before remediation can succeed.

Prevention Strategies

Long-term measures to prevent black mold recurrence on ceilings.

| Prevention Method | Effectiveness | Implementation Cost | Maintenance Required | Longevity |

|---|---|---|---|---|

| Improved Ventilation | High | Moderate | Regular cleaning | 10-15 years |

| Mold-Resistant Materials | High | High | Minimal | 15-20 years |

| Humidity Control | Very High | High | Filter replacement | 10-12 years |

| Regular Maintenance | Moderate | Low | Ongoing inspection | Continuous |

| Thermal Insulation | Moderate | High | None | 20+ years |

Humidity control provides most effective long-term mold prevention.

Material Replacement Options

Mold-resistant alternatives for replacing affected plasterboard ceilings.

| Replacement Material | Mold Resistance | Water Resistance | Installation Cost | Aesthetic Options |

|---|---|---|---|---|

| Type MR Gypsum | Good | Moderate | Baseline | Paint/texture |

| PVC Laminated | Excellent | High | +30% | Various patterns |

| Fiber Cement | Excellent | High | +50% | Paint finish |

| Aluminum Panels | Excellent | Complete | +80% | Multiple finishes |

| Vinyl Planks | Excellent | Complete | +40% | Wood-look options |

PVC laminated offers best balance of performance and cost.

Conclusion

Stop gypsum ceiling sagging in Georgetown's humidity using moisture-resistant Type MR board, 300-400mm joist spacing, proper vapor barriers, adequate ventilation, and humidity control below 60% through dehumidification systems. PVC laminated gypsum tiles provide excellent mold resistance for coastal homes through impermeable surface barriers, antimicrobial additives, and easy maintenance though proper installation with sealed edges remains essential. Best moisture-resistant bathroom materials include aluminum composite panels, PVC ceiling planks, fiber cement boards, and marine-grade plywood prioritizing zero water absorption and easy maintenance in high-humidity environments. Black plasterboard ceilings result from mold growth caused by moisture condensation, poor ventilation, thermal bridging, or water leaks requiring moisture source elimination, affected area removal, improved ventilation, and mold-resistant materials. Success with tropical ceiling systems requires understanding that high humidity demands moisture-resistant materials and proper support spacing, mold prevention requires both material selection and environmental controls, bathroom ceilings need materials with zero water absorption and antimicrobial properties, and black mold indicates systemic moisture problems requiring comprehensive remediation including ventilation improvements and humidity control, making moisture management the critical factor for ceiling longevity in tropical climates.