Many people view gypsum ceilings as simple decorative surfaces without understanding their systematic engineering approach. Recognizing gypsum ceiling components and functionality helps optimize installation decisions and performance expectations for various building applications.

A gypsum ceiling is a suspended ceiling system using gypsum board panels attached to metal or wood framing to create smooth, level interior surfaces that provide fire resistance, sound control, and concealed space for utilities while offering design flexibility.

Through decades of manufacturing gypsum board and working with contractors on ceiling installations, I learned that gypsum ceilings represent complete building systems rather than simple decorative treatments, requiring systematic understanding for optimal performance and longevity.

What is Gypsum Tile and How Does it Differ?

Understanding gypsum tile characteristics helps distinguish between different gypsum ceiling products. Gypsum tiles offer specific advantages for certain applications while differing significantly from standard gypsum board panels in installation and performance.

Gypsum tiles are pre-finished gypsum panels typically measuring 2x2 or 2x4 feet with decorative surfaces or textures, designed for drop-in ceiling grid systems that provide easy installation, maintenance access, and acoustic performance in commercial applications.

Comprehensive Gypsum Tile Analysis and Application Optimization

Gypsum tiles represent specialized ceiling products that serve distinct applications where standard gypsum board may not provide optimal solutions. During my experience working with commercial contractors and facility managers, I learned that understanding gypsum tile characteristics helps select appropriate ceiling systems for specific performance requirements and maintenance needs.

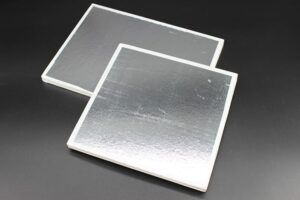

Manufacturing differences between gypsum tiles and standard gypsum board create products optimized for different installation methods and performance characteristics. Gypsum tiles typically incorporate reinforcing materials, specialized edge treatments, and factory-applied finishes that eliminate field finishing requirements while providing enhanced durability for commercial applications.

Grid system compatibility represents a primary advantage of gypsum tiles since they integrate directly with standard suspended ceiling grid systems without requiring additional framing or finishing work. This compatibility allows easy integration with lighting, HVAC systems, and other ceiling-mounted equipment while maintaining access for maintenance and modifications.

Acoustic performance often exceeds standard gypsum board ceilings since gypsum tiles can incorporate specialized backing materials, perforations, or surface treatments that enhance sound absorption and reduce noise transmission. Commercial applications benefit from improved acoustic environments that enhance productivity and comfort.

Maintenance advantages include individual tile replacement capability that allows facility managers to address damage or staining without disrupting entire ceiling areas. This replaceability reduces maintenance costs and downtime compared to continuous gypsum board ceilings that require extensive repairs for localized damage.

Fire performance characteristics may differ from standard gypsum board depending on tile construction and grid system integration. Some gypsum tiles achieve enhanced fire ratings through specialized formulations while others may have reduced performance due to grid system vulnerabilities. Understanding fire requirements helps ensure appropriate product selection.

Moisture resistance varies among gypsum tile products with some formulations providing enhanced performance in high-humidity environments while others maintain standard gypsum characteristics. Application-specific selection ensures optimal performance in challenging moisture conditions.

Design flexibility includes various surface textures, patterns, and edge treatments that provide aesthetic options beyond standard flat gypsum board surfaces. Decorative options allow ceiling systems to contribute to interior design goals while maintaining functional performance characteristics.

Cost considerations include higher material costs offset by reduced installation labor and finishing requirements compared to standard gypsum board systems. Life-cycle cost analysis should include installation, maintenance, and replacement factors to determine optimal ceiling system selection for specific applications.

| Product Characteristic | Gypsum Tiles | Standard Gypsum Board | Application Advantage |

|---|---|---|---|

| Installation method | Drop-in grid system | Screw/nail attachment | Speed, access |

| Finishing requirements | Factory finished | Field finishing required | Labor savings |

| Maintenance approach | Individual replacement | Section repair | Reduced disruption |

| Acoustic performance | Often enhanced | Standard | Noise control |

| Design options | Various textures/patterns | Flat surface | Aesthetic flexibility |

| Fire performance | Varies by product | Consistent standard | Application dependent |

Is Gypsum Good for Ceiling Applications?

Understanding gypsum performance characteristics helps evaluate its suitability for various ceiling applications. Gypsum offers specific advantages and limitations that affect ceiling system selection and long-term performance expectations.

Gypsum excels in ceiling applications through fire resistance, dimensional stability, easy installation, and cost-effectiveness, though it requires moisture protection and proper support systems to achieve optimal performance in challenging environments or heavy loading conditions.

Comprehensive Performance Evaluation and Application Suitability

Gypsum ceiling performance depends on understanding material characteristics and matching them to specific application requirements. During my experience working with diverse building types and performance requirements, I learned that gypsum provides excellent ceiling solutions when properly specified and installed for appropriate applications.

Fire resistance represents gypsum's primary performance advantage in ceiling applications since gypsum contains chemically combined water that provides fire protection through endothermic reactions during heating. This fire performance makes gypsum suitable for fire-rated assemblies and buildings requiring enhanced fire protection.

Dimensional stability allows gypsum ceilings to maintain flat, crack-free surfaces under normal building conditions when properly installed with appropriate framing and joint treatment. Gypsum's low thermal expansion and moisture stability prevent the warping and movement that can affect other ceiling materials.

Installation efficiency benefits from gypsum's workability with standard construction tools and techniques that allow rapid installation by skilled crews. Gypsum cuts easily, accepts standard fasteners, and integrates well with building systems, reducing installation time and labor costs compared to more complex ceiling materials.

Cost effectiveness makes gypsum ceiling systems accessible for various project budgets while providing reliable performance. Material costs, installation efficiency, and long-term durability combine to create favorable life-cycle economics for most ceiling applications.

Moisture limitations require consideration in high-humidity environments where standard gypsum may experience softening, mold growth, or dimensional changes. Moisture-resistant gypsum formulations address these limitations for bathroom, kitchen, and basement applications where standard products may not perform adequately.

Weight considerations favor gypsum for ceiling applications since lightweight characteristics reduce structural loading while maintaining adequate strength for typical ceiling requirements. Reduced weight allows larger spans and simpler framing systems compared to heavier ceiling materials.

Surface quality provides smooth, uniform finishes suitable for various decorative treatments including paint, texture, and wallcoverings. Gypsum accepts finishing materials well while providing consistent appearance across large ceiling areas.

Integration capability with building systems allows gypsum ceilings to accommodate lighting, HVAC, electrical, and other systems through standard cutting and mounting techniques. This flexibility supports modern building design requirements for integrated ceiling systems.

Repair and maintenance procedures for gypsum ceilings use standard materials and techniques familiar to most contractors, reducing long-term maintenance costs and complexity. Damage repair typically involves standard patching and refinishing procedures that restore original appearance and performance.

Environmental considerations include gypsum's natural mineral composition and recyclability that support sustainable building practices. Gypsum production and disposal have relatively low environmental impact compared to synthetic ceiling materials.

| Performance Factor | Gypsum Rating | Key Advantages | Limitation Areas |

|---|---|---|---|

| Fire resistance | Excellent | Chemical water content | None significant |

| Moisture resistance | Good (with proper products) | MR formulations available | Standard products limited |

| Installation ease | Excellent | Standard tools and techniques | Requires skilled finishing |

| Cost effectiveness | Excellent | Low material and labor costs | None significant |

| Dimensional stability | Excellent | Low movement characteristics | Requires proper support |

| Weight efficiency | Excellent | Lightweight construction | None significant |

How Many Years Does a Gypsum Ceiling Last?

Understanding gypsum ceiling lifespan helps set realistic expectations and plan maintenance schedules. Ceiling longevity depends on installation quality, environmental conditions, and maintenance practices rather than predetermined expiration dates.

Gypsum ceilings typically last 20-30 years in normal indoor environments with proper installation and maintenance, though well-maintained systems in favorable conditions can provide 40+ years of service while challenging environments may require earlier replacement or renovation.

Comprehensive Longevity Analysis and Life Extension Strategies

Gypsum ceiling lifespan varies significantly based on multiple factors that building owners can influence through proper specification, installation, and maintenance practices. During my experience tracking ceiling performance across various building types and climates, I learned that understanding longevity factors helps optimize ceiling investments and maintenance planning.

Installation quality represents the primary factor affecting gypsum ceiling lifespan since proper framing, fastening, and joint treatment prevent premature failure and maintain appearance throughout the service life. Professional installation with appropriate materials and techniques ensures ceilings achieve their full potential longevity.

Environmental conditions significantly affect gypsum ceiling performance with stable temperature and humidity conditions promoting maximum lifespan while extreme conditions or frequent fluctuations can accelerate deterioration. Climate-controlled buildings typically achieve longer ceiling life than structures with variable environmental conditions.

Maintenance practices directly influence ceiling longevity through regular inspection, prompt repair of minor damage, and periodic refinishing that maintains appearance and prevents deterioration progression. Proactive maintenance extends ceiling life significantly compared to reactive approaches that address problems after extensive damage occurs.

Building use intensity affects ceiling wear patterns and maintenance requirements with high-traffic commercial buildings creating more demanding conditions than residential applications. Understanding use patterns helps establish appropriate maintenance schedules and longevity expectations for specific building types.

Moisture exposure represents the primary threat to gypsum ceiling longevity since water damage can cause staining, mold growth, and structural deterioration that requires replacement. Proper building envelope maintenance and prompt leak repairs prevent moisture-related ceiling damage.

Structural movement in buildings can cause ceiling cracking and joint failure that affects appearance and may require repair or replacement. Proper expansion joint design and flexible installation details accommodate normal building movement while preventing ceiling damage.

Renovation cycles often determine practical ceiling replacement timing since building updates may require ceiling modifications that make replacement more economical than repair. Planning ceiling replacement during major renovations optimizes project costs and minimizes disruption.

Performance degradation patterns help predict maintenance needs and replacement timing through understanding how ceilings age and deteriorate under specific conditions. Regular assessment allows proactive replacement planning that prevents emergency situations and optimizes project scheduling.

Quality variations between installation contractors and materials affect baseline ceiling quality and potential longevity. Premium materials and skilled contractors provide better long-term performance while economy approaches may require more frequent maintenance or earlier replacement.

Technology improvements in gypsum products and installation methods can extend ceiling longevity beyond historical expectations through enhanced moisture resistance, improved joint systems, and better installation practices that address traditional failure modes.

| Longevity Factor | Impact Level | Typical Range | Optimization Strategy |

|---|---|---|---|

| Installation quality | Very High | 15-40+ years | Professional contractors, quality materials |

| Environmental stability | High | 20-35 years | Climate control, moisture management |

| Maintenance quality | High | 20-40+ years | Regular inspection, prompt repairs |

| Building use intensity | Moderate | 15-30 years | Appropriate specifications for use level |

| Moisture exposure | Very High | 5-40+ years | Leak prevention, moisture-resistant products |

| Structural stability | Moderate | 20-35 years | Proper expansion joints, flexible details |

Conclusion

Gypsum ceilings provide cost-effective, fire-resistant interior surfaces lasting 20-30+ years through systematic installation of gypsum panels on supporting frameworks, with longevity depending on proper installation quality, environmental control, and maintenance practices rather than material limitations alone.