Current 1/2 inch gypsum board prices in Guyana range from GYD $1,800-2,500 per sheet (4x8 feet) for standard grade, with moisture-resistant boards at GYD $2,200-3,000 per sheet, fire-rated boards at GYD $2,800-3,500 per sheet, and prices varying by supplier, quantity ordered, and delivery location, with Georgetown suppliers offering competitive rates while remote area delivery adds 15-25% transportation costs.

Standard grade 1/2 inch gypsum board costs GYD $1,800-2,500 per 4x8 foot sheet depending on brand and supplier location. Moisture-resistant boards for bathroom and kitchen applications cost GYD $2,200-3,000 per sheet with enhanced performance. Fire-rated boards for commercial applications range GYD $2,800-3,500 per sheet with specialized additives. Bulk purchasing over 100 sheets typically reduces costs by 10-15% from retail pricing. Delivery costs add GYD $300-500 per truck load within Georgetown and 15-25% more for remote locations.

From my extensive experience in the Guyana market, I've observed that prices fluctuate significantly based on import costs and seasonal demand, particularly during the dry construction season.

How Many Sheets of Drywall Are Needed for a Standard 3-Bedroom Guyana House?

A standard 3-bedroom Guyana house requires approximately 85-110 sheets of 1/2 inch drywall (4x8 feet) covering 2,700-3,500 square feet of wall and ceiling surface area, including bedrooms (25-30 sheets), living areas (20-25 sheets), kitchen/dining (15-20 sheets), bathrooms (10-15 sheets), ceilings (25-35 sheets), with 10% waste factor for cuts and repairs.

Total surface area for standard 3-bedroom house ranges 2,700-3,500 square feet requiring 85-110 sheets of 4x8 foot drywall. Bedroom areas need 25-30 sheets for three bedrooms with standard ceiling heights. Living areas including living room and hallways require 20-25 sheets depending on open floor plan. Kitchen and dining areas use 15-20 sheets with additional considerations for cabinet areas. Bathroom coverage needs 10-15 sheets using moisture-resistant board for wet areas. Ceiling installation requires 25-35 sheets depending on house footprint and architectural features.

Room-by-Room Drywall Requirements

Detailed breakdown of drywall sheet requirements for standard 3-bedroom Guyana house construction.

| Room Area | Wall Coverage | Ceiling Coverage | Total Sheets | Board Type | Special Considerations |

|---|---|---|---|---|---|

| Master Bedroom | 8-10 sheets | 4-5 sheets | 12-15 sheets | Standard | Closet areas |

| Bedroom 2 | 6-8 sheets | 3-4 sheets | 9-12 sheets | Standard | Window openings |

| Bedroom 3 | 6-8 sheets | 3-4 sheets | 9-12 sheets | Standard | Door openings |

| Living Room | 10-12 sheets | 6-8 sheets | 16-20 sheets | Standard | Open ceiling |

| Kitchen | 8-10 sheets | 3-4 sheets | 11-14 sheets | Moisture-resistant | Cabinet backing |

| Dining Room | 6-8 sheets | 3-4 sheets | 9-12 sheets | Standard | Combined with living |

| Bathrooms (2) | 8-10 sheets | 2-3 sheets | 10-13 sheets | Moisture-resistant | Wet area protection |

| Hallways | 4-6 sheets | 2-3 sheets | 6-9 sheets | Standard | Traffic areas |

Moisture-resistant board required for kitchen and bathroom applications.

House Size Variations

Drywall requirements for different house sizes common in Guyana residential construction.

| House Type | Floor Area | Wall Height | Total Sheets | Standard Sheets | MR Sheets | Estimated Cost |

|---|---|---|---|---|---|---|

| Small 3BR | 1,000 sq ft | 9 feet | 85-95 sheets | 70-80 sheets | 15 sheets | GYD $180,000-220,000 |

| Standard 3BR | 1,200 sq ft | 9 feet | 95-105 sheets | 80-90 sheets | 15-20 sheets | GYD $210,000-260,000 |

| Large 3BR | 1,400 sq ft | 10 feet | 105-115 sheets | 85-95 sheets | 20-25 sheets | GYD $240,000-300,000 |

| Executive 3BR | 1,600 sq ft | 10 feet | 115-125 sheets | 90-100 sheets | 25-30 sheets | GYD $270,000-340,000 |

Higher ceilings significantly increase drywall requirements and costs.

Waste Factor and Additional Materials

Essential considerations for accurate drywall quantity estimation and project planning.

| Factor | Percentage | Sheet Quantity | Cost Impact | Planning Consideration |

|---|---|---|---|---|

| Cutting Waste | 5-8% | 5-8 extra sheets | Minor | Normal construction |

| Damage Allowance | 2-3% | 2-3 extra sheets | Minimal | Handling/transport |

| Future Repairs | 3-5% | 3-5 extra sheets | Storage cost | Long-term planning |

| Design Changes | 5-10% | 5-10 extra sheets | Moderate | Flexible planning |

| Total Waste Factor | 10-15% | 10-15 extra sheets | Budget accordingly | Standard practice |

10% minimum waste factor recommended for residential projects.

Can I Use Regular Gypsum Board for Bathroom Ceilings in Guyana?

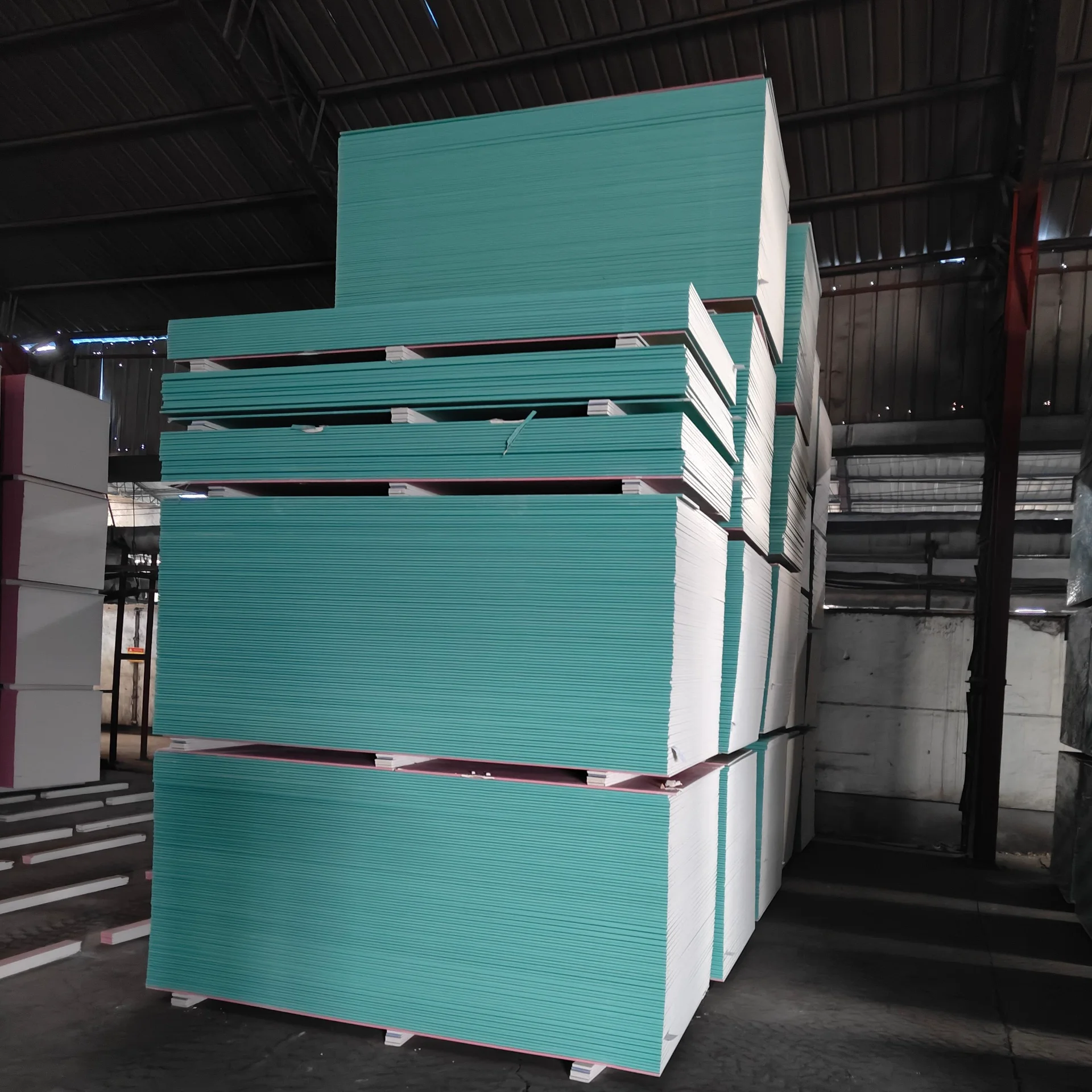

Regular gypsum board should not be used for bathroom ceilings in Guyana due to high humidity and poor ventilation, instead use moisture-resistant (green board) or cement board with proper vapor barriers, ventilation systems, and mold-resistant finishes, as regular board will deteriorate rapidly in tropical bathroom conditions leading to sagging, mold growth, and structural failure.

High humidity levels in Guyana bathrooms cause regular gypsum board to absorb moisture leading to sagging and structural failure. Moisture-resistant board (green board) contains additives that resist water absorption and mold growth in humid conditions. Cement board provides superior moisture resistance for extreme wet conditions with longer service life. Proper ventilation systems including exhaust fans reduce moisture accumulation and extend board life. Vapor barriers behind drywall prevent moisture penetration into wall cavities and structural elements.

Moisture Resistance Comparison

Performance characteristics of different board types in Guyana bathroom ceiling applications.

| Board Type | Moisture Resistance | Service Life | Cost Factor | Installation Difficulty | Maintenance Requirement |

|---|---|---|---|---|---|

| Regular Gypsum | Poor | 1-2 years | 1.0x | Standard | High replacement |

| Moisture-Resistant | Good | 5-8 years | 1.3x | Standard | Moderate maintenance |

| Cement Board | Excellent | 10+ years | 2.0x | Complex | Minimal maintenance |

| PVC Panels | Excellent | 8-12 years | 1.8x | Moderate | Easy cleaning |

| Aluminum Composite | Excellent | 15+ years | 2.5x | Professional | Minimal maintenance |

Moisture-resistant board provides best balance of cost and performance.

Ventilation Requirements

Essential ventilation specifications for bathroom ceiling installations in tropical climates.

| Ventilation Element | Specification | Performance | Installation | Maintenance |

|---|---|---|---|---|

| Exhaust Fan | 80 CFM minimum | Humidity removal | Electrical connection | Monthly cleaning |

| Duct System | Insulated to exterior | Condensation prevention | Professional install | Annual inspection |

| Intake Vents | Passive or active | Air circulation | Simple installation | Quarterly cleaning |

| Humidity Control | 60% RH maximum | Mold prevention | Automatic operation | Sensor calibration |

Proper ventilation essential for any ceiling material success.

Installation Best Practices

Proper installation techniques for bathroom ceilings in high-humidity tropical environments.

| Installation Aspect | Best Practice | Quality Standard | Common Mistakes | Prevention Method |

|---|---|---|---|---|

| Vapor Barrier | 6mm plastic sheeting | Complete coverage | Gaps and tears | Sealed joints |

| Fastener Spacing | 200mm centers | Structural integrity | Wide spacing | Professional install |

| Joint Sealing | Moisture-proof compound | Water-tight seams | Standard compound | MR materials |

| Primer/Paint | Mold-resistant coating | Surface protection | Standard paint | Anti-microbial |

Professional installation critical for tropical bathroom applications.

How to Repair Water-Damaged Drywall After Guyana's Flood Season?

Repair water-damaged drywall after Guyana's flood season by first ensuring complete drying for 48-72 hours, cutting out damaged sections 12 inches beyond visible damage, treating exposed framing with anti-microbial solution, installing new moisture-resistant drywall with vapor barriers, applying mold-resistant primer and paint, and implementing improved ventilation to prevent future moisture problems.

Complete drying for 48-72 hours using fans and dehumidifiers prevents mold growth and allows accurate damage assessment. Cut damaged sections 12 inches beyond visible water damage to ensure complete contaminated material removal. Anti-microbial treatment of exposed framing kills existing mold spores and prevents future growth. Moisture-resistant drywall replacement provides better performance in future flood conditions. Mold-resistant primer and paint create protective surface against humidity and moisture intrusion.

Damage Assessment and Removal

Systematic approach to evaluating and removing water-damaged drywall after flooding.

| Assessment Stage | Evaluation Method | Action Required | Safety Precaution | Timeline |

|---|---|---|---|---|

| Initial Inspection | Visual and moisture meter | Document damage extent | PPE equipment | Day 1 |

| Structural Check | Frame and electrical | Professional assessment | Power disconnection | Day 1-2 |

| Contamination Level | Water source analysis | Sanitization protocol | Respiratory protection | Day 2 |

| Mold Detection | Visual and air testing | Remediation planning | Containment measures | Day 2-3 |

| Material Removal | Cut beyond damage | Complete extraction | Dust control | Day 3-5 |

Professional assessment recommended for extensive flood damage.

Drying and Treatment Process

Essential steps for proper drying and anti-microbial treatment before reconstruction.

| Process Step | Method | Duration | Equipment Needed | Success Criteria |

|---|---|---|---|---|

| Water Extraction | Pumps and wet vacuums | 6-12 hours | Professional equipment | No standing water |

| Air Circulation | Fans and blowers | 24-48 hours | Industrial fans | Constant airflow |

| Dehumidification | Industrial dehumidifiers | 48-72 hours | Commercial units | <60% humidity |

| Anti-microbial Treatment | Spray application | 24 hours | PPE and sprayer | Complete coverage |

| Final Drying | Continued ventilation | 24-48 hours | Ongoing equipment | <19% moisture content |

Moisture content below 19% required before new installation.

Reconstruction Best Practices

Improved installation techniques to prevent future water damage and enhance resilience.

| Improvement Area | Standard Practice | Enhanced Method | Cost Impact | Long-term Benefit |

|---|---|---|---|---|

| Board Selection | Regular gypsum | Moisture-resistant | +30% | 3x longer life |

| Vapor Barriers | Optional | Required installation | +15% | Moisture protection |

| Elevation | Floor level | 6-12 inches higher | +25% | Flood resistance |

| Ventilation | Basic exhaust | Enhanced systems | +40% | Humidity control |

| Finishes | Standard paint | Mold-resistant coatings | +20% | Easy maintenance |

Enhanced methods provide significant flood resistance improvement.

Prevention Strategies

Long-term measures to minimize future water damage in flood-prone areas.

| Prevention Method | Implementation | Effectiveness | Cost Factor | Maintenance |

|---|---|---|---|---|

| Elevated Installation | Raise electrical/HVAC | Very High | High | Minimal |

| Flood Vents | Foundation openings | High | Medium | Annual check |

| Drainage Improvement | Site grading/drainage | High | Medium | Seasonal clear |

| Sump Pump System | Basement/crawl space | Very High | High | Monthly test |

| Emergency Planning | Preparation procedures | Medium | Low | Regular updates |

Elevated installation most effective for repeat flood areas.

Conclusion

Current 1/2 inch gypsum board prices in Guyana range GYD $1,800-2,500 per sheet for standard grade with moisture-resistant boards at GYD $2,200-3,000 and bulk purchasing reducing costs by 10-15%. Standard 3-bedroom Guyana house requires 85-110 sheets covering 2,700-3,500 square feet with 10% waste factor including bedrooms (25-30 sheets), living areas (20-25 sheets), kitchen/dining (15-20 sheets), and ceilings (25-35 sheets). Regular gypsum board should not be used for bathroom ceilings in Guyana due to high humidity, instead use moisture-resistant board or cement board with proper ventilation and vapor barriers. Water-damaged drywall after flood season requires complete drying for 48-72 hours, cutting damage 12 inches beyond visible damage, anti-microbial treatment, and moisture-resistant replacement with improved ventilation. Success with gypsum board in Guyana requires understanding that tropical climate conditions significantly impact material selection and pricing, proper quantity estimation includes waste factors and room-specific requirements, moisture-resistant materials are essential for high-humidity applications like bathrooms, and flood damage repair demands systematic drying and enhanced reconstruction methods, making climate-appropriate material selection and installation techniques critical for long-term performance in tropical environments.