When contractors ask me, "What type of construction is drywall?", they're really asking about how this material fits into building classification systems.

Drywall is a lightweight, non-load-bearing interior wall system classified as Type V construction in building codes. It creates finished surfaces through gypsum panels attached to framing rather than wet plastering or masonry methods.

From years of working with builders, I've learned that drywall represents a fundamental shift in construction philosophy—from permanent, heavy assemblies to modular, adaptable systems that prioritize speed and flexibility over traditional mass.

What Is the Purpose of Drywall?

Understanding drywall's purpose reveals why it became the dominant interior wall system.

Drywall serves multiple purposes: creating smooth finished surfaces, fire resistance, sound control, thermal insulation, and concealing utilities while providing a base for paint, wallpaper, or other finishes. It replaces traditional wet plaster with a faster, more consistent system.

Primary Functions in Modern Construction

Through analyzing building performance across different applications, drywall's multifunctional nature becomes clear.

| Function | Performance Benefit | Code Requirement | Typical Application |

|---|---|---|---|

| Fire Resistance | 30-120 minute ratings | Required for egress paths | Fire-rated assemblies |

| Sound Control | STC 35-55+ ratings | Varies by occupancy | Residential/commercial separation |

| Smooth Finish | Paint-ready surface | Aesthetic standard | All interior spaces |

| Utility Concealment | Hidden wiring/plumbing | Safety requirement | Throughout buildings |

| Thermal Performance | Insulation compatibility | Energy codes | Exterior wall assemblies |

The integration capability is what makes drywall so valuable—it solves multiple building needs in a single system.

What Is Drywall Construction?

Drywall construction represents a complete building methodology, not just a finishing technique.

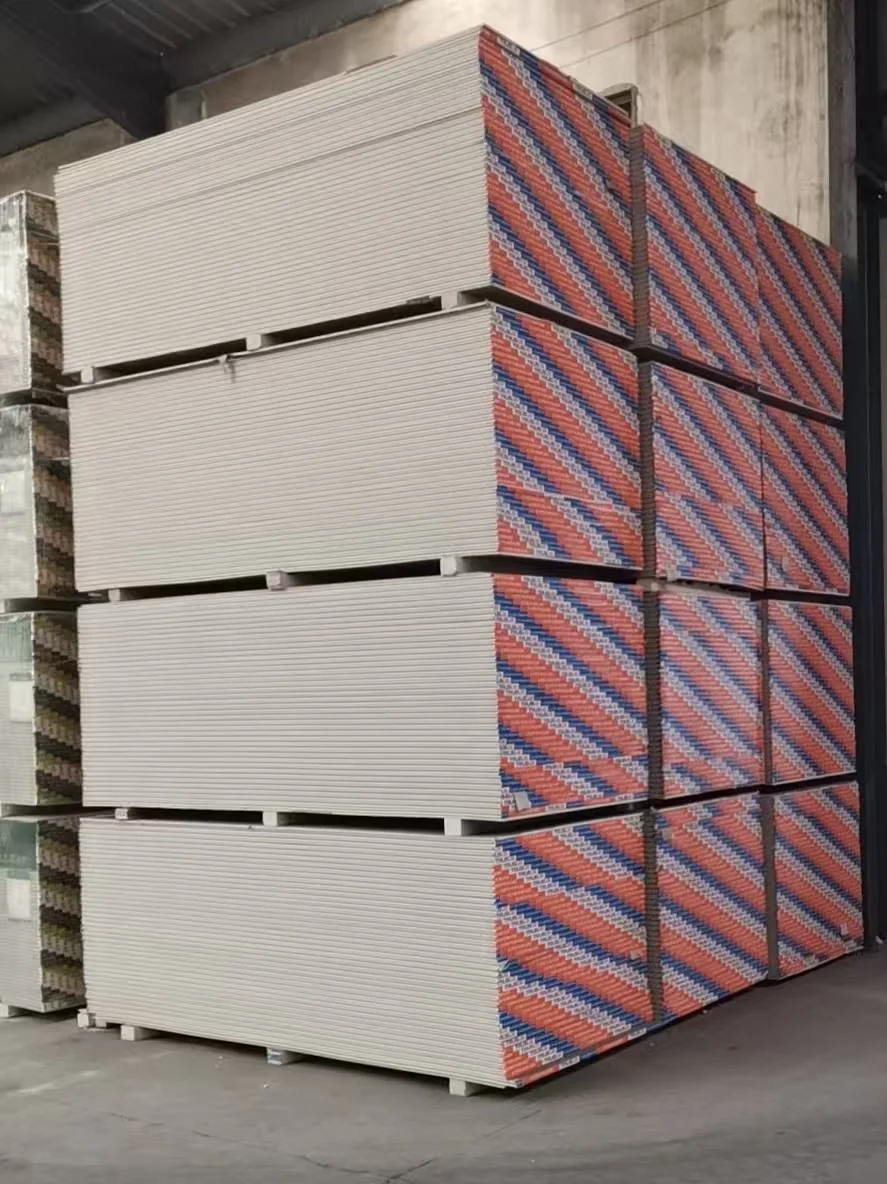

Drywall construction is a lightweight framing system using steel or wood studs with gypsum board panels to create interior partitions and ceiling assemblies. This method emphasizes speed, consistency, and modularity over traditional heavy construction.

Drywall Construction Components

From overseeing countless installations, the system's effectiveness comes from the integration of standardized components.

| Component | Material | Function | Standard Sizes |

|---|---|---|---|

| Framing | Steel studs or wood | Structural support | 16" or 24" o.c. spacing |

| Gypsum Panels | Gypsum core, paper face | Finish surface | 4'×8', 4'×10', 4'×12' |

| Fasteners | Screws or nails | Panel attachment | Type specific to substrate |

| Joint Treatment | Tape and compound | Seamless appearance | Paper, mesh, or fiberglass |

| Corner Protection | Metal or plastic beads | Damage resistance | Various profiles available |

The standardization of components allows for consistent quality and predictable installation timelines across projects.

Why Do American Houses Use Drywall?

This question touches on the cultural and economic factors that drove drywall's adoption.

American houses use drywall because it delivers speed, cost efficiency, and performance that matches the scale and pace of American residential construction. The system evolved to meet demands for affordable housing, rapid suburban development, and standardized construction practices.

Historical and Economic Drivers

Through studying construction evolution, several factors converged to make drywall the American standard.

| Factor | Traditional Method | Drywall Advantage | Impact on Adoption |

|---|---|---|---|

| Speed | Wet plaster: 3-4 coats, drying time | Ready for paint in days | 50-70% faster installation |

| Labor Skills | Specialized plasterers required | General contractors can install | Expanded installer base |

| Material Cost | Lath, multiple plaster coats | Single-component system | 30-40% material savings |

| Quality Control | Variable craft skill results | Consistent factory quality | Predictable outcomes |

| Repairability | Difficult to patch seamlessly | Cut out and replace sections | Lower maintenance costs |

| Climate Adaptability | Humidity-sensitive curing | Controlled manufacturing | Works in all climates |

The economic efficiency combined with performance reliability made drywall the logical choice for America's post-war housing boom and continues driving its use today.

Conclusion

Drywall represents a lightweight, non-load-bearing construction system that serves multiple building functions including fire resistance, sound control, and finished surfaces. As a construction type, it prioritizes speed, consistency, and modularity over traditional heavy building methods. American houses adopted drywall because it efficiently delivers the performance, cost-effectiveness, and installation speed needed for large-scale residential construction. This system transformed building from craft-based to manufacturing-based processes, making quality interior finishes accessible and affordable across diverse applications.