The Guyana government is promoting light steel framing for Silica City to achieve rapid construction timelines reducing housing delivery from years to months, cost-effective building systems lowering construction costs by 30-40%, climate resilience against hurricanes and seismic activity, sustainable development reducing concrete usage by 80%, skilled labor efficiency requiring fewer specialized workers, and modular construction enabling systematic urban expansion with consistent quality standards.

Rapid construction timelines enable housing delivery in 3-6 months compared to 12-18 months for traditional concrete construction. Cost reduction of 30-40% makes affordable housing accessible to middle-income families. Climate resilience provides hurricane resistance and seismic performance exceeding traditional construction. Sustainable development reduces concrete usage by 80% and construction waste by 60%. Skilled labor efficiency reduces dependency on specialized trades enabling faster workforce development. Modular systems enable systematic expansion with consistent quality across large developments.

From my extensive experience working with government housing initiatives across the Caribbean, I've observed that TRUSUS light steel framing systems provide the perfect combination of speed, quality, and affordability that modern urban development projects require.

How Quickly Can a Light Steel Villa be Assembled in Guyana's New Housing Schemes?

A light steel villa using TRUSUS systems can be assembled in Guyana's new housing schemes within 4-6 weeks for complete structural frame, 8-10 weeks for full weatherproof enclosure, 12-16 weeks for complete interior finishing, enabling families to move in within 4 months compared to 12-18 months for traditional construction methods.

Structural frame assembly takes 4-6 weeks with TRUSUS precision engineered components and standardized connections. Weatherproof enclosure achieved in 8-10 weeks including wall systems, roofing, and exterior cladding. Interior finishing completed in 12-16 weeks with integrated services and quality finishes. Total occupancy timeline of 4 months represents 70% time saving over traditional methods. Quality control maintained through factory precision and systematic assembly processes.

TRUSUS Assembly Timeline Breakdown

Detailed construction phases for light steel villa assembly using TRUSUS systems.

| Construction Phase | Duration | Key Activities | TRUSUS Components | Quality Milestones |

|---|---|---|---|---|

| Foundation Prep | 1-2 weeks | Site preparation, footings | Anchor bolt templates | Level verification |

| Frame Assembly | 2-3 weeks | Wall frames, roof trusses | C-studs, tracks, connectors | Structural inspection |

| Structural Complete | 4-6 weeks | Full frame erected | Complete TRUSUS system | Engineering approval |

| Envelope Installation | 6-8 weeks | Sheathing, roofing, windows | Gypsum board, insulation | Weatherproof achievement |

| MEP Installation | 8-12 weeks | Electrical, plumbing, HVAC | Service integration | Systems testing |

| Interior Finishing | 12-16 weeks | Drywall, flooring, fixtures | Final TRUSUS components | Final inspection |

Systematic approach ensures consistent quality and timeline adherence.

Critical Success Factors

Key factors ensuring rapid assembly success in Guyana's housing schemes.

| Success Factor | Implementation Strategy | TRUSUS Advantage | Performance Impact | Risk Mitigation |

|---|---|---|---|---|

| Component Precision | Factory manufacturing | ±1mm tolerance | Perfect fit assembly | Eliminates field adjustments |

| Logistics Coordination | Just-in-time delivery | Standardized packaging | Minimal site storage | Reduces material handling |

| Crew Training | Certified installers | Simplified connections | Faster learning curve | Reduces errors |

| Quality Control | Systematic inspection | Integrated checklists | Consistent standards | Prevents rework |

| Weather Protection | Rapid enclosure | Quick weatherproofing | Continuous work | Eliminates delays |

Systematic approach eliminates traditional construction bottlenecks.

What are the Load-Bearing Capacities of C-Studs for Guyana Multi-Story Builds?

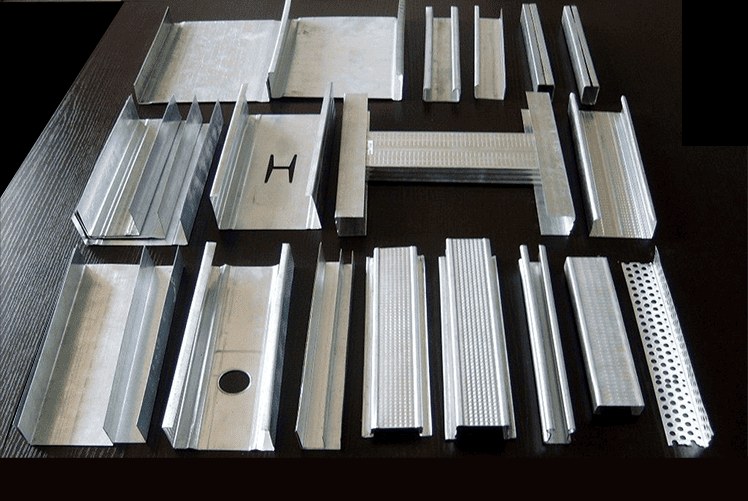

TRUSUS C-studs for Guyana multi-story builds provide load-bearing capacities of 12-15 kN per stud for 92mm sections, 18-22 kN per stud for 146mm sections, supporting 3-4 story residential construction with proper engineering design, meeting AISI S100 structural standards, and offering 25% safety factor margins above design loads with hot-dip galvanized corrosion protection for tropical environments.

92mm C-studs handle 12-15 kN loads suitable for residential applications up to 3 stories. 146mm C-studs provide 18-22 kN capacity supporting commercial loads and 4-story construction. Structural engineering design optimizes load paths and stud spacing for maximum efficiency. AISI S100 compliance ensures code approval for multi-story applications. Safety margins of 25% above design loads provide structural reliability. Hot-dip galvanizing offers 75-year corrosion protection in coastal environments.

Multi-Story Design Considerations

Engineering considerations for multi-story light steel construction in Guyana.

| Design Aspect | Engineering Requirement | TRUSUS Solution | Performance Standard | Code Compliance |

|---|---|---|---|---|

| Lateral Stability | Shear wall design | Integrated bracing system | Wind load resistance | IBC/ASCE compliance |

| Deflection Control | L/240 serviceability | Engineered stud spacing | Comfort standards | Structural codes |

| Connection Design | Moment transfer | Proprietary connectors | Load path continuity | AISI standards |

| Fire Rating | 2-hour assemblies | Gypsum board systems | Life safety | Fire codes |

| Seismic Design | Ductile response | Flexible connections | Earthquake resistance | Seismic codes |

Comprehensive engineering ensures safe multi-story performance.

What Thickness of Steel Track is Standard for Guyana Commercial Partitions?

Standard steel track thickness for Guyana commercial partitions is 0.60mm for light-duty office partitions, 0.75mm for standard commercial applications, 1.00mm for heavy-duty and fire-rated assemblies, with TRUSUS tracks meeting ASTM A1003 standards, providing structural integrity for 3-4 meter heights, and offering corrosion resistance through galvanized coating systems.

0.60mm thickness suitable for light office partitions up to 3 meters height with standard loads. 0.75mm thickness provides standard commercial performance for most applications with enhanced durability. 1.00mm thickness required for heavy-duty assemblies, fire ratings, and heights exceeding 3.5 meters. ASTM A1003 compliance ensures structural performance and code approval. Galvanized coating provides corrosion protection in high-humidity environments. Track systems integrate with TRUSUS studs for complete partition solutions.

Commercial Partition Performance Standards

Performance requirements for commercial partition systems in tropical climates.

| Performance Criteria | Standard Requirement | TRUSUS Performance | Testing Method | Compliance Level |

|---|---|---|---|---|

| Structural Integrity | No visible deflection | <L/240 deflection | Load testing | Exceeds standard |

| Fire Resistance | 1-2 hour rating | Up to 4 hours | ASTM E119 | Superior rating |

| Sound Transmission | STC 45-55 | STC 50-65 | ASTM E90 | High performance |

| Impact Resistance | 40J impact | 60J+ resistance | Impact testing | Enhanced durability |

| Moisture Resistance | No degradation | Galvanized protection | Humidity testing | Tropical rated |

TRUSUS systems exceed commercial performance standards.

Installation and Quality Control

Installation procedures and quality control for commercial track systems.

| Installation Phase | Procedure | Quality Check | Tolerance | Performance Impact |

|---|---|---|---|---|

| Layout Survey | Precise positioning | Laser level verification | ±3mm | Partition alignment |

| Track Fastening | Structural attachment | Pull-out testing | Design loads | Structural integrity |

| Plumb and Level | Accurate installation | Multi-point checking | ±1.5mm/m | System performance |

| Connection Details | Proper joining | Visual inspection | Complete engagement | Load transfer |

| Final Inspection | System verification | Performance testing | Code compliance | Warranty validation |

Precise installation critical for optimal system performance.

Sustainability and Environmental Impact

Environmental benefits of TRUSUS light steel track systems.

| Environmental Aspect | Impact Measurement | TRUSUS Advantage | Sustainability Benefit | Certification |

|---|---|---|---|---|

| Material Efficiency | 95% recyclable content | Steel recyclability | Resource conservation | LEED credits |

| Construction Waste | <5% waste generation | Precision manufacturing | Waste minimization | Green building |

| Energy Efficiency | Thermal bridging control | Thermal breaks available | Energy savings | Energy codes |

| Indoor Air Quality | Zero VOC emissions | Inert materials | Health benefits | GREENGUARD |

| Lifecycle Impact | 75+ year service life | Durability design | Long-term value | Sustainable design |

Comprehensive sustainability supports green building initiatives.

Conclusion

Guyana government promotes light steel framing for Silica City to achieve rapid construction reducing housing delivery from years to months, cost-effective systems lowering costs by 30-40%, climate resilience against hurricanes, sustainable development reducing concrete usage by 80%, skilled labor efficiency, and modular construction enabling systematic expansion.